Safety signs can be a mix of symbols, colours and words. On a recent vacation in the United Kingdom, I saw a configuration of pedestrian crossing signs that challenged my interpretation of signs I had seen since I was a child. I wondered if this new configuration still communicated the essential safety message.

Category: signs

Simpsons safety reaches Australia after 5 years and at twice the price

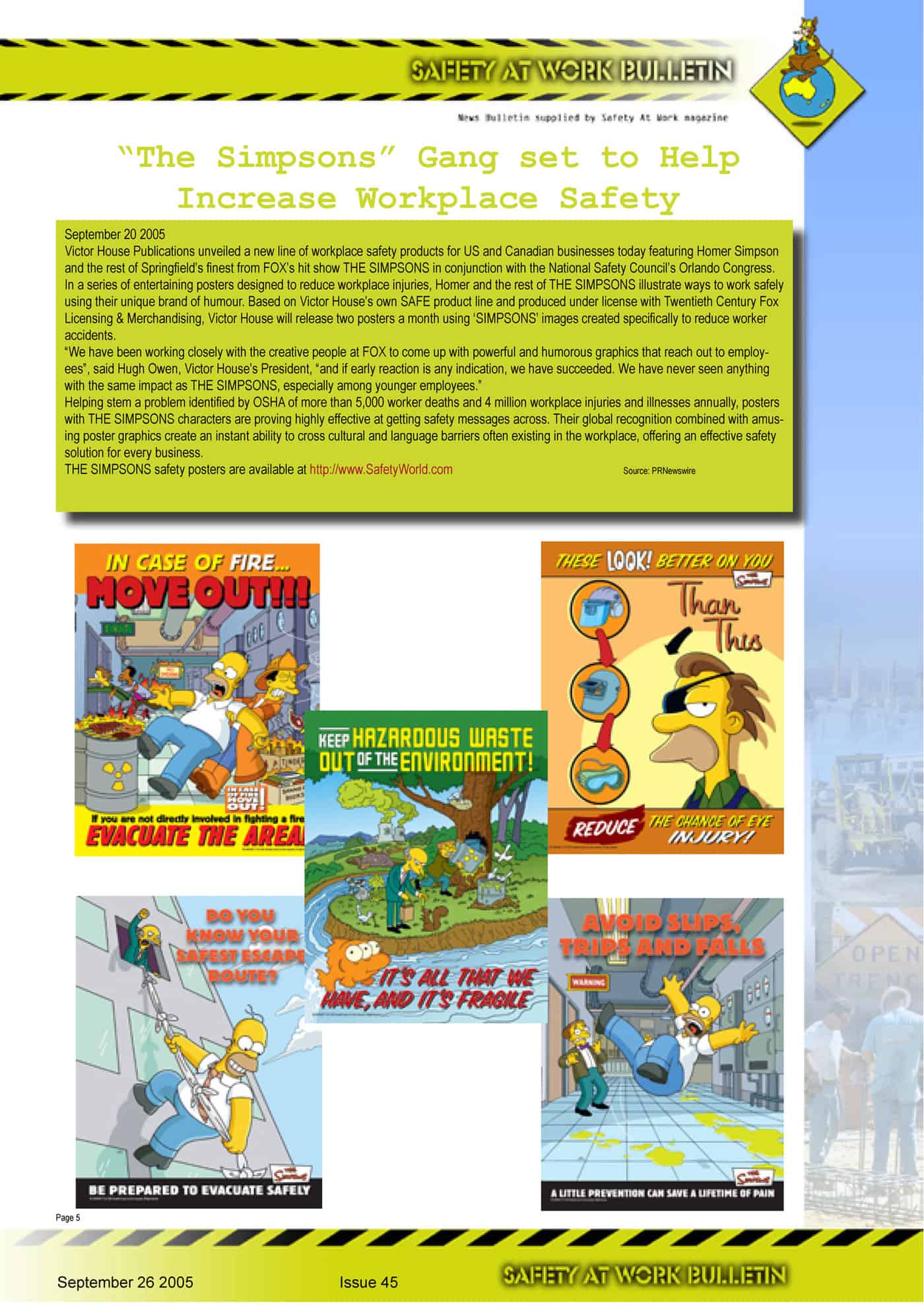

In 2005, a series of safety posters based on The Simpson TV characters was released in support of the National Safety Council’s Orlando Congress, as reported in SafetyAtWork Bulletin at the time, picture right). The posters have finally reached Australia and will be unveiled at the Safety In Action exhibition on 2 April 2010. They are sure to be popular.

In 2005, a series of safety posters based on The Simpson TV characters was released in support of the National Safety Council’s Orlando Congress, as reported in SafetyAtWork Bulletin at the time, picture right). The posters have finally reached Australia and will be unveiled at the Safety In Action exhibition on 2 April 2010. They are sure to be popular.

A small selection of Simpsons posters will be available through WorkSafety Solutions, the Australian distributor. Many more have been added through the original US distributor, SafetyWorld since the original launch. Continue reading “Simpsons safety reaches Australia after 5 years and at twice the price”

No guard = hand injuries + $50k penalty

Machine guarding is one of the most effective and longstanding control measures for occupational hazards. Sometimes safety people even get excited about them. Equally safety people, regulators and magistrates, get angry when the guards are left off.

One company in South Australia on 1 February 2010 received two penalties for similar hand injuries that occurred only days apart in 2007. Continue reading “No guard = hand injuries + $50k penalty”

Serious injuries can occur regardless of good OHS intentions

SafeWork South Australia has illustrated a situation that is common in Australian workplaces – no matter how hard one tries to ensure safety, things can still go wrong. In a court case on 20 November 2009, four farm operators were fined over a foreseeable incident that cost a 20-year-old the sight in one eye as well a fractured skull and paralysis, from falling three metres. According to a SafeWorkSA media release

“The incident occurred in May 2006 as the farmhand, aged in his early 20’s, was working on a large stock crate prior to mustering sheep for shearing. The crate had been borrowed from a neighbour. The farmhand had to stand on a small platform three metres off the ground and operate a manual winch to lower a ramp within the crate.During this task, the winch handle forcefully struck the man in the face, after which he fell from the platform to the ground. This resulted in skull fractures and the loss of sight in his right eye, and spinal damage, which left him paralysed.”

The farmers had preventative management measures in place prior to the incident and have made considerable changes to the workplace to enable the worker to return to work.

The comments of Industrial Magistrate Stephen Lieschke in his judgement are worth noting

“While (they) believed they were being comprehensive in their safety improvements, they appear not to have given the same attention to the stock crate as to their own plant and equipment, probably because it was occasionally borrowed to them.”

The defendants were fined $A28,000, a hefty fine compared to some given out in the same jurisdiction. This figure was after a higher than usual 30% penalty reduction. Industrial Magistrate Lieschke applied the discount because of an “exceptionally high level of demonstrated contrition”. The magistrate puts it this way

The defendants were fined $A28,000, a hefty fine compared to some given out in the same jurisdiction. This figure was after a higher than usual 30% penalty reduction. Industrial Magistrate Lieschke applied the discount because of an “exceptionally high level of demonstrated contrition”. The magistrate puts it this way“General deterrence does require a substantial penalty due to the prevalence of serious injury from the obvious danger of unprotected work at height, and due to the need for employers to take a structured risk assessment and control approach to all work processes and plant.

As first offenders the defendants are each exposed to a maximum fine of $100,000. In my opinion a notional total penalty based on a starting point of a fine of $40,000 is appropriate after taking account of all the above circumstances. After reduction by 30% this results in an aggregate penalty of $28,000. This in turn results in a fine of $7,000 for each defendant.

I also record a conviction against each defendant.”

Amputations, shocks and burns – court cases

In late October 2009, there were several OHS court cases in Australia that raise issues that need to be kept at the forefront of the thoughts of safety managers, safety professionals, workers and business owners.

Amputation

One case in South Australia identified the need to have sufficient detail in policies and procedures for workers to be safe. The comment of Industrial Magistrate Michael Ardlie is particularly important.

Beerenberg Pty Ltd was fined $A9,000 dollars for breaching OHS law

“The incident happened in May 2007 at the company’s Hahndorf premises. A female employee was operating a mincer as part of the process of producing green tomato chutney.

The court was told that at the conclusion of the task, the employee switched off the machine but noticed a piece of tomato hanging from the mincer plate. She went to flick the piece off, but in doing so lost the tip of her index finger.

SafeWork SA’s investigation concluded that the woman’s finger had gone through one of the holes in the mincer plate and come into contact with the cutting blade behind, which was still winding down after the machine was switched off.

The fingertip could not be reattached, but the woman returned to work with the business after five weeks. Aside from the cosmetic appearance, there remains some numbness in the finger.

In his penalty decision today, Industrial Magistrate Michael Ardlie acknowledged that while there was a safe operating procedure written and a warning sign in place, these measures alone were insufficient.

“(The measures) did not specifically warn employees of the dangers presented by the moving parts of the mincer after the mincer had been turned off… the procedures in place did not go far enough.”

Since the incident, the company has fitted a purpose-built distance guard as well as an interlock that shuts the machine down once the guard is removed.”

Magistrate Ardlie fined the defendant $9,000 this being its first offence.

Crushed Fingers and Guarding

The same Industrial Magistrate as above, McArdlie, had to deal with a very different case. Whereas Beerenberg was facing its first offence, OE & DR Pope are on their fifth.

“SafeWork SA prosecuted OE & DR Pope Pty Ltd after investigating an incident at its Wingfield printing plant in March 2007.

A 34-year-old male employed as a machine operator, suffered crush injuries to three fingers of his right hand, which were caught between moving rollers. While he returned to work after three weeks, he suffered residual sensitivity problems, and left the business in December 2007 for unrelated reasons.

The court was told that the operator had attempted to clean dry spots from a roller without stopping the machine, and was able to gain access to the moving parts through a 70mm gap in the guarding. Furthermore, the employee’s usual assistant was not available leaving him to perform two roles on the machine. The supervisor who also should have been present was elsewhere on the premises at the time.

In his decision on penalty handed down today, Industrial Magistrate Michael Ardlie noted that the machine involved had replaced another involved in a previous injury, but that a risk assessment failed to identify the problem which ultimately occurred:

“Whilst the defendant prior to the incident did assess the machine, installed a guard and introduced a Standard Operating Procedure, the steps it took were inadequate.”

The court was told that this was the company’s fifth offence dating back to 1998, and all previous incidents resulted in similar injuries from similar circumstances.

Therefore, being a subsequent offence under the Occupational Health Safety and Welfare Act 1986, the defendant faced a maximum fine of $A200,000. Magistrate Ardlie fined the company $A40,000.”

Fifth incident in just over ten years – “similar injuries from similar circumstances”. The reduced fine of $A40,000 seems a little odd in this context.

There are several elements that are disturbing in this case – ineffective guarding, excessive or conflicting workload and absent work supervisor.

Overhead Hazards

Just as falling in some workplaces is as “easy as falling of a log”, so it is that many people forget to look up. A court case in Western Australia has fined Shrigley Drilling Contractors $A40,000 after one worker was shocked and another burnt when their drilling rig tilted into high-voltage overhead powerlines in 2006.

“Laurence Victor Shrigley – trading as Shrigley Drilling Contractors – pleaded guilty to failing to ensure that the workplace was safe and, by that failure, causing serious harm to another person and was fined in the Perth Magistrates Court this week.

In May 2006, Western Power had contracted Outback Power Services to perform works and construct a voltage regulator at Eneabba. Outback Power had contracted Mr Shrigley to perform drilling works.

On May 17, Mr Shrigley and an electrical contractor were engaged in drilling holes with a drilling rig underneath power lines. The position in which the drilling contractor chose to place the rig required him to raise the mast very close to the power lines.

In repositioning the rig, the left-hand outrigger was raised and the mast tilted towards the power lines. The mast touched the power lines and Mr Shrigley received an electric shock and was thrown backwards from the drilling rig.

Another man, who was driving the truck that carried the drilling rig and was working with Mr Shrigley on a voluntary basis, also received an electric shock serious enough to set his clothing on fire. He sustained burns to around 60 per cent of his body.

The court heard that no formal pre-start meeting had been held before the work commenced, and no directions were given for the work, with the exception of where the holes were required to be placed.

Mr Shrigley had not checked whether the power lines were live, or attempted to make any arrangements for the power in the area to be isolated.”

The features in this case include contractor management, using a volunteer, inadequate preparation, and inadequate number of workers (apparently, no spotter).

It is understandable that cynicism is rampant in the safety profession when the same work practices lead to injuries in the 21st century just as they did in the 20th and sometimes in the 19th.

Safety signs – fact and fiction

A while ago I had a gig where one of the aspects of the job was researching how safety signs work, are read and responded to. Here’s a snapshot of some facts and fiction about safety signs.

Fact: If people don’t know the reason for a safety sign, they will probably ignore it. A safety sign needs to be seen as a reminder about a danger and the associated injury precautions that should already have been discussed at a safety meeting or included in training. Workers need to understand the relevancy of a safety sign, and that includes getting info on what the danger really is. A related issue is that research on how people respond to road signs found that likelihood of being hurt is a big factor in whether people take notice of a sign.* It’s reasonable to conclude there is a nexus with how people respond to safety signs generally; just telling people what to do is not enough, knowledge is essential.

Fiction: A safety warning sign is sometimes all that’s needed to cover the safety problem.

Fact: A safety warning sign is never enough to control a danger. If you’ve done nothing more than put up a warning sign to control a risk, it’s odds on you will be breaking the law. Don’t look at a warning sign as the end of the issue; look at it as the indicator that you know there is a safety problem in an area and that special safety precautions are needed and are in place. That’s exactly how the OH&S enforcement agency sees them. That latter point is worth thinking about if your workplace is a place that plasters safety signs up everywhere but doesn’t deliver on actual risk controls.

Fiction: The sign is permanent, so is the message.

Fact: Safety signs should be changed, repositioned and even re-coloured every now and then to make them noticeable. That old, grime covered sign plonked up on the wall becomes invisible eventually. People get used to seeing a sign, and the message stops registering. Try revitalising how the safety messages work. Try ways to get people to “connect” with their safety signs. One thing worth trying is to get staff to have a go at spraying up the safety message themselves. Use the key words on a commercially available sign, but let staff “funk it up” and get creative. That will make the sign more noticeable, more “real” – a very good thing. If producing a sign from scratch doesn’t suit, use customised sign options provided by most commercial sign suppliers.

Col Finnie

col@finiohs.com

* There’s a wealth of useful information in the 1998 research paper titled “Signs of trouble to come? A behavioural assessment of the effectiveness of road warning signs – Final Report”, Austin Adams, Jim Bright, Ben Searle, School of Psychology, The University of New South Wales.