Dr Tony Lower has written an opinion piece in the December 2011 edition of the Medical Journal of Australia (not available without a subscription however a related media release is) about farm safety. One statistic he quotes says:

“In tractors, rollover fatalities have decreased by 60% after the introduction of regulations requiring compulsory rollover protection structures.”

The very successful introduction of rollover protection structures (ROPS) in Australia was given a major boost by OHS regulators offering substantial rebates for the fitting of ROPS on top of the regulatory requirements. A safety “spoonful of sugar” as it were.

Over time, regulations can become onerous as new regulations are imposed to address new hazards or the lack of compliance by business. This can lead to accusations of red tape. But it could be argued that some of the legislative complexity stems from businesses not complying with the initial laws. Is it possible to break the cycle?

Tony Lower implies that the new Work Health and Safety Act in Australia has the potential to radically change the management of “powered mobile plant”, in agriculture this would principally apply to quad bikes and tractors. Lower explains that

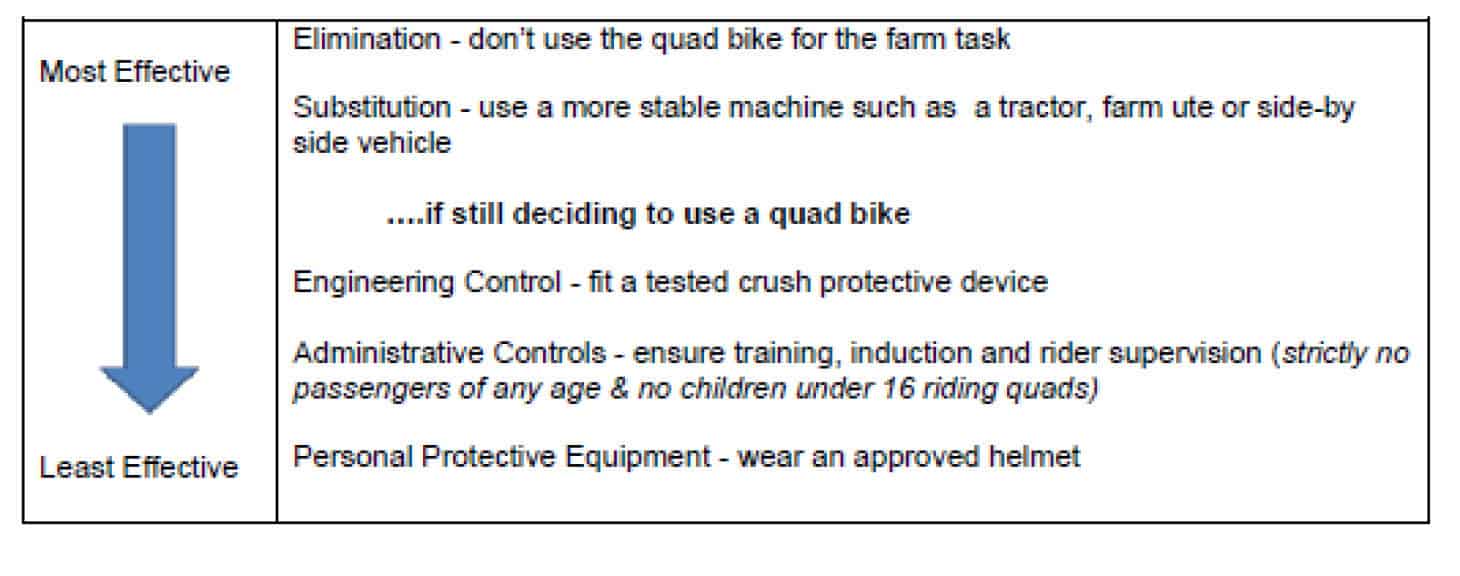

“From 1 January 2012, the new national Model Work Health and Safety Regulations 2011 will require that all “powered mobile plant” (including tractors, field machinery and quad bikes) must manage risk in accordance with the hierarchy of controls…, including risks of overturning. The quad bike industry continues to rely on training and helmets — low order solutions in the hierarchy of controls — to minimise risks. Given the new regulations require these risks to be managed “so far as is reasonably practicable”, this is unlikely to be adequate.” [link integrated]

Previous OHS Acts in Australia stated aims such as eliminating risks “at the source” but this was never given the same emphasis in regulations and so became aspirational rather than operational. By requiring by law that risks are managed to the hierarchy of controls, employers must demonstrate that the elimination and substitution of risks are not possible and that engineering controls are not available before applying administrative controls and personal protective clothing.

Previous OHS Acts in Australia stated aims such as eliminating risks “at the source” but this was never given the same emphasis in regulations and so became aspirational rather than operational. By requiring by law that risks are managed to the hierarchy of controls, employers must demonstrate that the elimination and substitution of risks are not possible and that engineering controls are not available before applying administrative controls and personal protective clothing.

It is likely to be difficult for the makers of quad bikes to argue that design changes that would reduce the likelihood of rollovers are not possible. However, if this could be argued it is likely that the engineering solution of crush protection devices is unavoidable, particularly with recent independent research that shows positive safety outcomes for such devices.

The cautious application of these new WHS laws could benefit society through the reduction of agricultural worker deaths to a similar extent to that achieved by the imposition of ROPS on tractors. It may be that the new laws will indeed break the cycle of prescription and self-regulation, at least, in relation to quad bikes. If this occurs, it will be a significant safety wedge in the safe design of all types of workplace machinery. And as almost all the quad bikes are manufactured outside Australia, international manufacturers and safety regulators will not be able to ignore the safety demands from the bottom of the world.

I’m an avid quad biker who rides for fun. Regardless, I agree with any laws that will make their use safer – I also think that a 16+ age limit is very sensible thinking indeed.

WorkSafe responds to QUAD BIKE DEATHS with proposed amendments to Code of Practice – Consultation now open

Following consultation with the rural industry, unions and the community, the Government is proposing to amend the Rural Plant Code of Practice 2004 so that, amongst other matters:

• quad bike and motorbike operators in workplaces are required to wear an approved and appropriate helmet

• children under 16 years of age are prohibited from operating adult quad bikes

• suppliers of quad bikes must provide information to purchasers about bike selection and use

• operators are correctly trained.

The proposed changes are now open for public comment until 31 March 2012 so that individuals and organisations can have their say and to ensure all issues affecting the rural industry are considered.

The Proposed amendments can be viewed here:

http://www.deir.qld.gov.au/workplace/events/commentconsult/index.htm

The relevant COP is preserved under the WHS Act 2011 from 1 January 2012

Now I deliberately left it until here to mention that this is a Queensland initiative – why did I do that?

Because regardless of where you are based, the Queensland COP will become part of the body of knowledge as to risks, and the means of controlling those risks – so the Queensland COP is something all businesses using quad bikes will have to factor in.

I believe that safety requirements such as this need to be extended to all quad bikes, regardless of use. This can only come about if all manufacturers voluntarily provided roll bars or had them fitted at POS, or Agencies such as Fair Trading stepped in to cover safety issues for quads sold for recreational purposes. Seat belts are compulsory in all vehicles, and not just those used for work Similar principles should apply to recreational quads and not just those used for work purposes.

If it stops needless deaths of farmworkers then I am all for it. I often think that they are a bit too casual for their own good and that is how they can end up getting hurt.

– Michael