Our experience with a global pandemic has blurred the lines between what is public health and what is occupational health. In that context, it’s worth considering the public health strategies and interventions. There are three levels of interventions: primary, secondary, and tertiary. Recently, on NPR’s All Things Considered, a public health specialist in the United States, Dr. Cedric Dark, discussed public health proposed strategies in relation to gun control in light of a recent report by the US Surgeon General.

Category: hierarchy of controls

We deserve new OHS ideas, research, initiatives, strategies, epiphanies and enlightenment

This week, the Australian Institute of Health and Safety (AIHS, formerly the Safety Institute of Australia) is hosting its national conference in Melbourne, Australia. The heyday of occupational health and safety (OHS) conferences seems to have passed in Australia as, perhaps, was confirmed by the varying responses to last year’s World Congress on Safety and Health at Work. But expectations for this week’s conference are high; at least mine are.

But are those expectations too high? There is a direct competitor for OHS ears and eyes (no matter the arguments) in the same building at the same time, the Workplace Health and Safety Show. The AIHS Conference needs to work hard to retain its prominence and, most importantly, its influence. It is worth reflecting on how this messy situation came about.

Farm Safety group video shows unclear position on quad bike safety

Farming is a unique industry with significant occupational health and safety (OHS) challenges; it is unique because it is a blend of rural culture, working at home often with children in the workplace, isolation from social services, self-reliance and independence. It is important for the OHS advice provided and promoted to offer the most effective health and safety advice. Many farming organisations provide this information and do it well. New Zealand’s Safer Farms appears to have good intentions but may have missed the mark with their latest video.

What was he thinking? A case study in risk assessment and intervention

Below is a video of a worker setting up their work area and dusting a retail sign. When one sees such videos or images, we naturally think, “What is he doing?” and “What was he thinking?” This article speculates on those questions and what could have been done.

Engineered stone in the business media

The Australian Financial Review (AFR) is a newspaper written for and about business, so worker safety and health is usually depicted as a nuisance to be addressed only when one absolutely must. However, its coverage of engineered stone products is notably skewed.

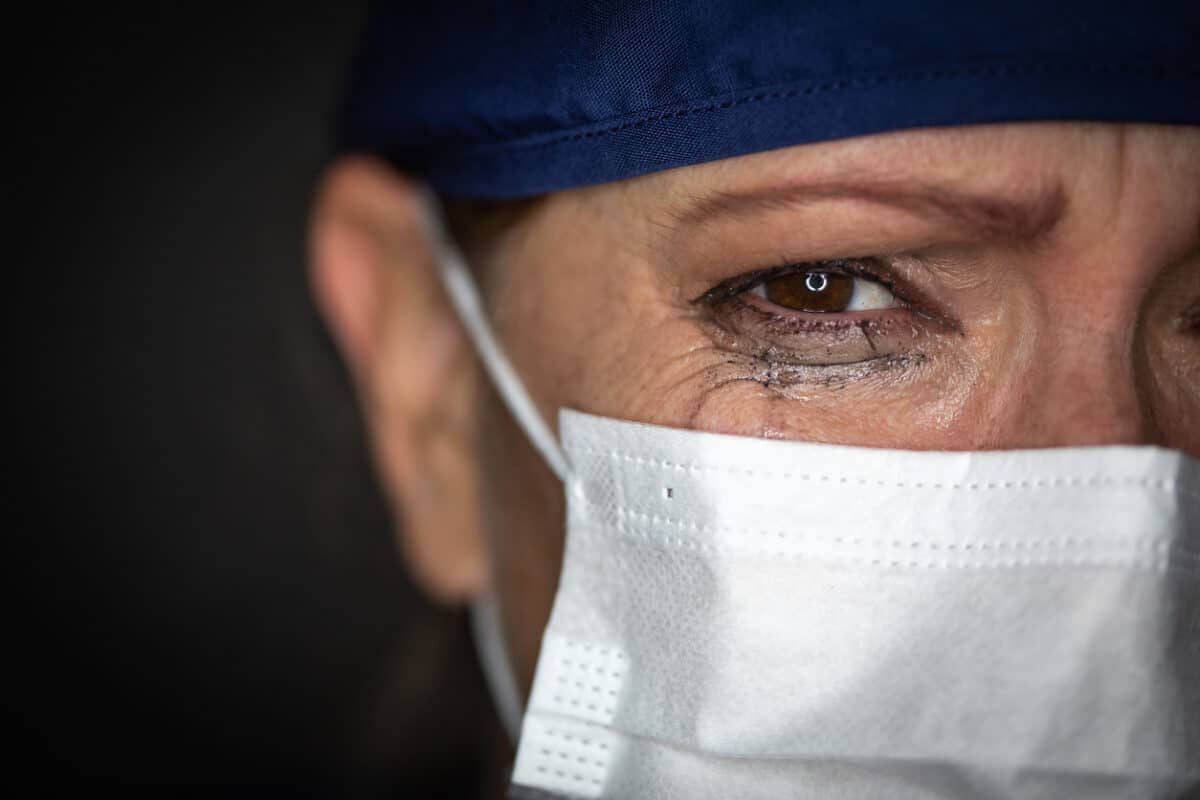

Moral distress = moral injury = workplace mental ill-health = burnout.

On December 29 2023, The Guardian newspaper’s cover story was about doctors in the United Kingdom’s National Health Service experiencing high rates of “moral distress”. It is common for hospitals and health care services to consider themselves as workplaces with unique hazards rather than suffering similar occupational health and safety (OHS) challenges to all other workplaces. What makes the OHS challenge so significant in the NHS is the size of the challenge rather than its nature or cause.

Australia is the first nation to ban engineered stone due to worker health concerns

The heads of Australian work health and safety authorities have decided to ban engineered stone from the middle of 2024. Some will seed this as a win for the trade union movement ( the unions certainly will), but many occupational health and safety and industrial hygiene professionals have been leading the way in obtaining the research evidence that made this decision such an easy one to make.