This week a national scaffolding safety campaign was launched in Australia. There are several sources for new and useful information about the campaign, two are below.

Mike Hammond of law firm, Deacons, has written a backgrounder on the need for the campaign and how to prepare for the compliance visits. Hammond lists the key messages form the campaign as

- “The campaign is designed to ensure compliance with existing workplace safety laws in relation to scaffolding;

- Increase industry awareness of the safety issues associated with using unsafe scaffolding;

- Recent incidents have highlighted a need to be vigilant when erecting, altering, using and dismantling scaffolding; and

- A wide range of trades that use scaffolding are exposed to significant risks of death and injury when the scaffolding does not comply with AS 1576.”

WorkSafe WA Commissioner Nina Lyhne said in a media release on 24 July 2009 that

“The construction industry is a high risk industry. Sadly, we still see a large number of injuries and deaths on construction sites.

WorkSafe [WA] focuses a lot of attention on education as well as on enforcement to reinforce the need for improved safety. Recent scaffolding incidents have led to the death of a number of workers and seriously injured others across Australia.

Industry is being advised of the intervention campaign, and inspectors from WA will be undertaking inspections over two months from 1 August to 30 September.”

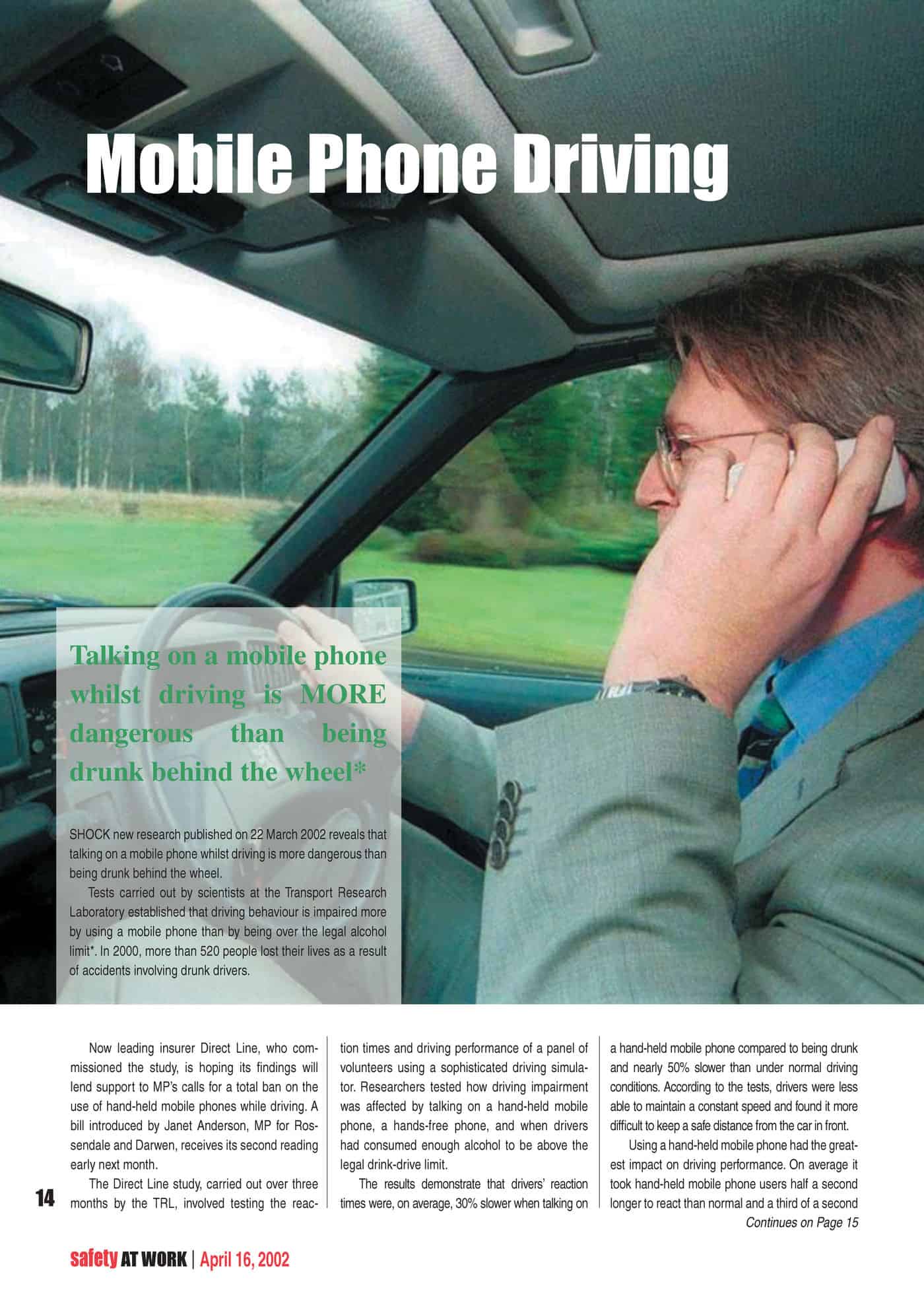

No US State has banned the practice because social use of mobile phones has become so widespread that any ban is impossible to enforce effectively.

No US State has banned the practice because social use of mobile phones has become so widespread that any ban is impossible to enforce effectively. The industrialised world, in particular, has been wrestling with the hazard of phones and driving for well over a decade. One

The industrialised world, in particular, has been wrestling with the hazard of phones and driving for well over a decade. One  According to a 2004 report by the US National Highway Traffic Safety Administration reported by UPI (unable to find a link)

According to a 2004 report by the US National Highway Traffic Safety Administration reported by UPI (unable to find a link)