Managing workplace absenteeism often ignores the OHS issues that are integral to the issue.

On 20 July 2009 the Chartered Institute of Personnel and Development released its findings on the issue in its annual Absence Management Survey.

On 20 July 2009 the Chartered Institute of Personnel and Development released its findings on the issue in its annual Absence Management Survey.

The media statement identifies the reasons for short- and long-term absences.

- “The main causes of short-term absence are minor illnesses such as colds and flu, stress and musculoskeletal conditions

- The main causes of long-term absence are acute medical conditions, stress and mental health conditions and musculoskeletal conditions and back pain.”

However, the media statement identifies no measures to counter these workplace hazards, preferring to focus on ancillary factors such as job security.

Willmott focuses on a comparison between absenteeism in the public and private sectors. The difference is statistically interesting, perhaps, but does not address the causes of absenteeism.

Willmot also illustrates the dominant HR position on absenteeism.

“Effective absence management involves finding a balance between providing support to help employees with health problems stay in and return to work and taking consistent and firm action against employees that try and take advantage of organisations’ occupational sick pay schemes.”

This manages the effect of the problem but not the problem itself which CIPD’s own research has identified as musculoskeletal conditions, stress, mental health and, to a lesser extent, colds and flu.

The comments by the Senior Public Policy Adviser for the CIPD, BenWillmott, are a good example of how some human resources or management organisations miss the health and safety element.

The CIPD does acknowledge the importance of workplace health and safety as illustrated by its reply to the Health & Safety Executive’s draft strategy. It also says in the Absence Management Survey that, in the return-to-work context:

“The involvement of occupational health professionals is identified as the most effective approach for managing long-term absence…”

However even though it sees itself as the “professional and accreditation body for the UK HR profession [which represents] over 130,000 HR professionals at every level of business and in every sector”, it hesitates to take a leadership role in health and safety. It’s a pity because applying the apparent professionalism of the Institute and its membership strength to OHS could achieve great social and business efficiencies.

For those wanting to look at comparison data, CIPD makes available its previous surveys for download.

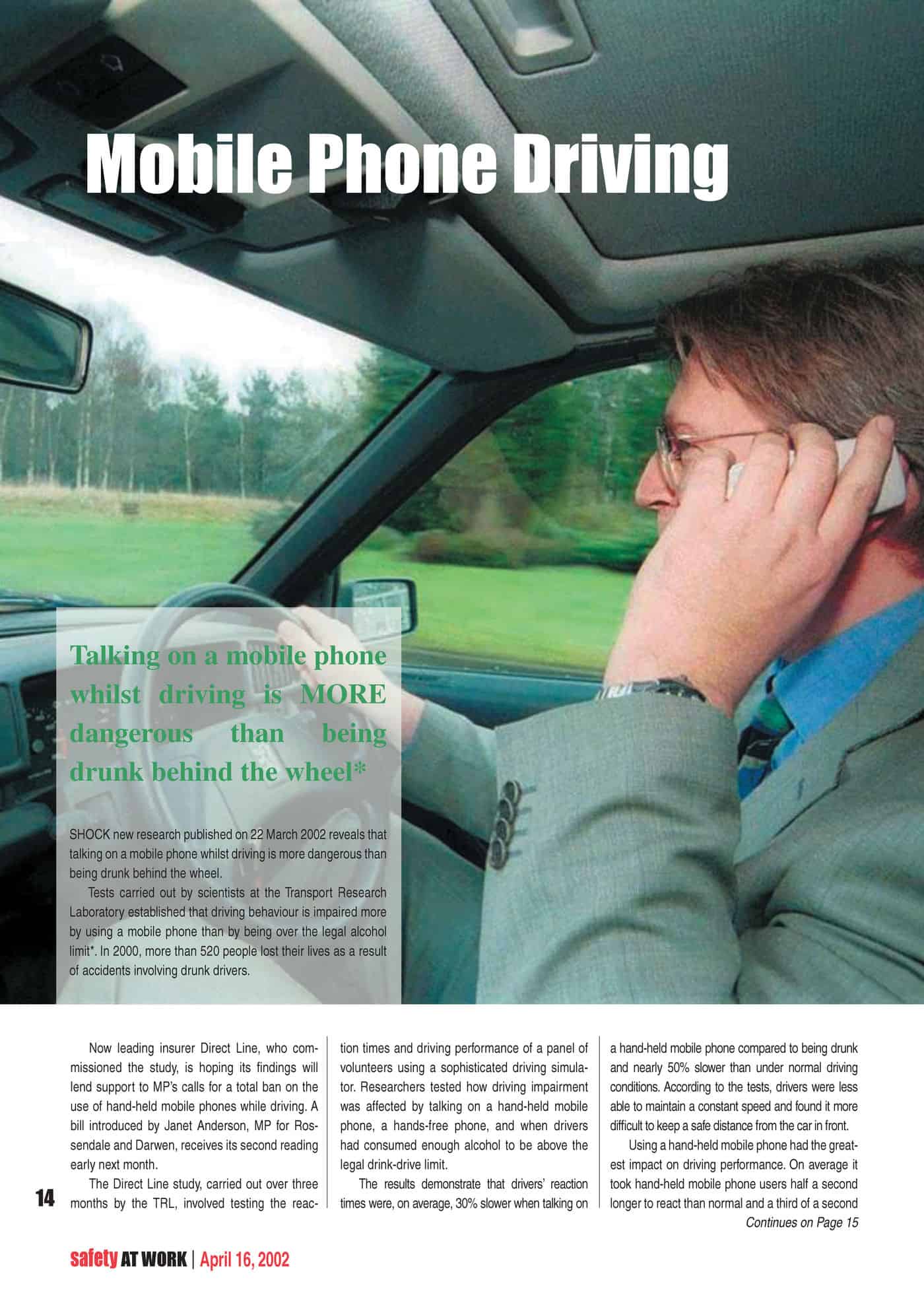

No US State has banned the practice because social use of mobile phones has become so widespread that any ban is impossible to enforce effectively.

No US State has banned the practice because social use of mobile phones has become so widespread that any ban is impossible to enforce effectively. The industrialised world, in particular, has been wrestling with the hazard of phones and driving for well over a decade. One

The industrialised world, in particular, has been wrestling with the hazard of phones and driving for well over a decade. One  According to a 2004 report by the US National Highway Traffic Safety Administration reported by UPI (unable to find a link)

According to a 2004 report by the US National Highway Traffic Safety Administration reported by UPI (unable to find a link)