2014 is going to present tough challenges to Australia’s politicians and corporate leaders. The Royal Commission into the Home Insulation Program, in particular, is going to illustrate and perhaps generate ideological conflict.

2014 is going to present tough challenges to Australia’s politicians and corporate leaders. The Royal Commission into the Home Insulation Program, in particular, is going to illustrate and perhaps generate ideological conflict.

The Home Insulation Program (HIP) was established quickly to address a looming economic crisis. Politicians and business leaders wanted Australia to avoid the global recession and they needed creative solutions. Various importance governance and safety elements appear to have been sacrificed to achieve the economic ends. In 2014, the politicians of the time and bureaucrats will be grilled over why they made these decisions. Various inquiries have already identified that these decisions contributed to the deaths of four young workers. In 2014, these decision- and policy-makers will be held to account for the fatal consequences of their economic decisions.

There has long been a conflict between the pursuit of profit and the pursuit of safe working conditions. The Royal Commission, and the surrounding debate, is likely to place this conflict squarely in the highest levels of Australia’s government and public service. Below are some of the issues that the Australian government and business sector are likely to face in 2014. Continue reading “Moral conflicts in store for Australian politicians and bureaucrats”

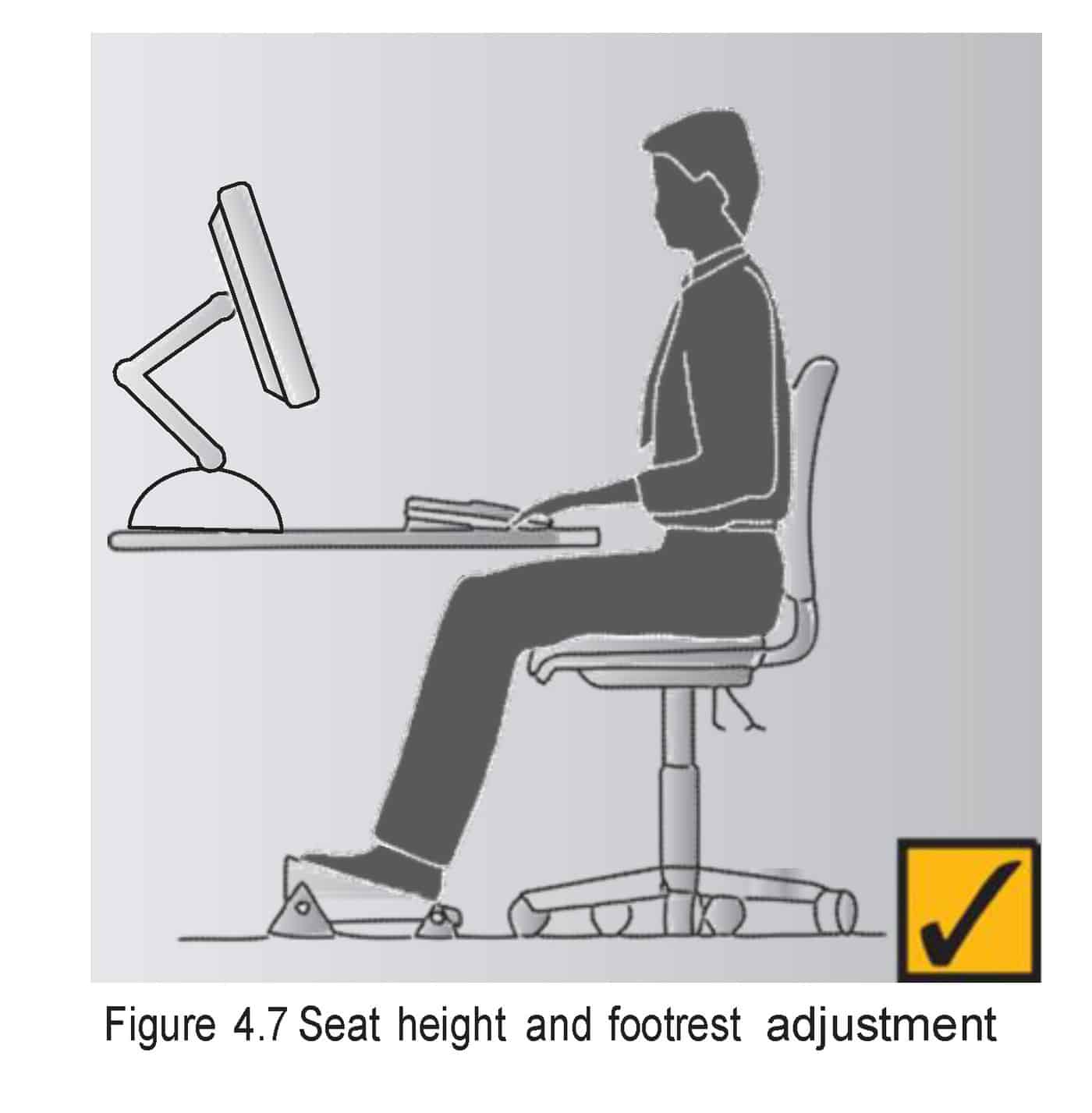

A diagram of safe posture at modern workstations has become iconic but it has also become a symbol of ergonomic misunderstanding. There are assumptions behind the angular figure about the way modern workers work, the equipment used and the tasks undertaken.

A diagram of safe posture at modern workstations has become iconic but it has also become a symbol of ergonomic misunderstanding. There are assumptions behind the angular figure about the way modern workers work, the equipment used and the tasks undertaken.