Radical Concept 1 – A vehicle can be workplace

Today the Australasian New Car Assessment Program (ANCAP) urged fleet managers to consider OHS obligations in their choice 0f work vehicles. ANCAP said

“Our understanding of the OH&S principles is that there is an obligation on companies and fleet managers to ensure a safe workplace.

“Vans certainly constitute a workplace under the legal definition. We would urge fleet purchasers to examine the legislation and then factor safety into their fleet purchasing policies.”

But in practice this creates enormous challenges for the fleet manager who may only have chosen vehicles in the past that were fit-for-purpose without considering the needs of the driver.

Only recently have steps been added to trucks to allow for easier access to goods on the rear trays. When technology became affordable tilt-down hydraulic ramps were installed, although these have their own work hazards. In both of these examples the changes occurred outside the cabin and related to accessing the transportable products. Looking after the physical and psychological needs of the driver as a worker is different.

For instance, emergency fire appliances in Australia have had substantially improved design over the last ten years. Many of the features are for the benefit of drivers and passengers, such as flip-out steps for when the vehicle is stationary or special seating to allow for personal protective clothing. But the cost of each of these new “safer” vehicles is such that the introduction is phased in and most likely as replacement vehicles. This process could take years. How can a workplace justify allowing only some workers to use “safer” workplaces? The churn of vehicles could establish an inequitable safety standard ion the workplace.

ANCAP’s argument seem to be that a fleet manager who chooses a vehicle that does not have the highest level of safety available are not providing a safe workplace. We could be back to determining what is reasonably practicable.

Radical Concept 2 – A road can be considered a workplace.

Some bus drivers consider their regular route to be a workplace. To some extent this is supported by the road traffic authorities who only allow certain speed control mechanisms on the roads that have bus traffic, such as speed islands rather than speed humps. Although this may be due to the needs of not knocking the passengers around as well.

Regardless of the whether it is passenger safety, pedestrian safety or public liability insurance that creates these design decisions, bus drivers take some “ownership” of their routes.

Important Consideration 1 – Vehicles have drivers

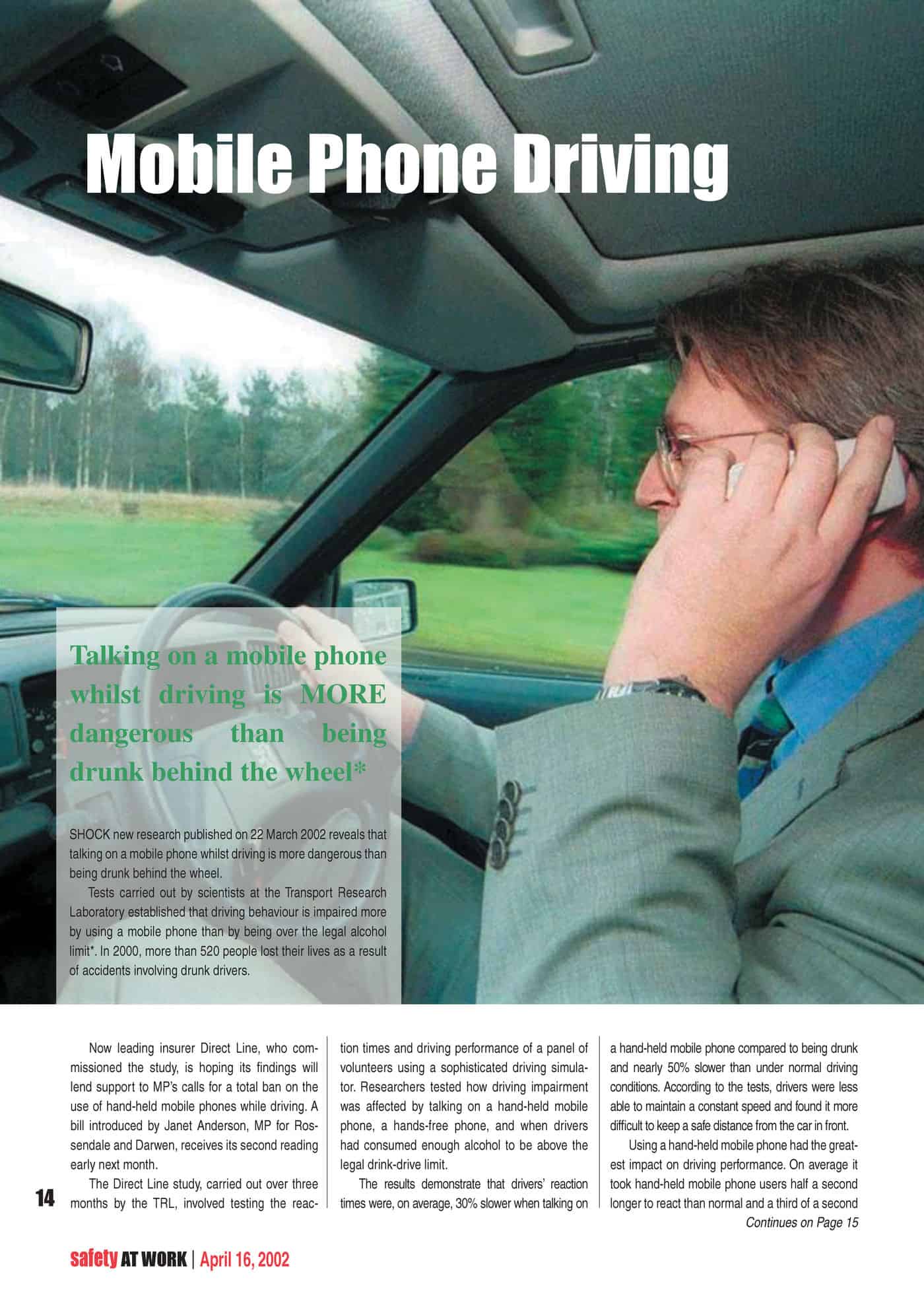

A lot of attention has been given to driver distraction and how drivers drive. Not only are there distractions from within the cabins from passengers, radios, phones, cigarette smoking and a range of driving activities, the relationship between external signage and driver response has also been high.

The complexity of the distraction issue can perhaps be summarized by a couple of recent links. In July 2009 a roadside memorial to a fatality itself is identified as having contributed to a fatality. Research in the United States has begun on the impact of roadside memorials but at the moment the jury is out.

“Our results showed that the number of red light violations was reduced by 16.7% in the 6 weeks after the installation of the mock memorials compared to the 6 weeks before whereas the number of violations at two comparison sites experienced an increase of 16.8%.”

Managers, fleet and OHS, also need to assess the suitability of their workers for driving and consider the following matters.

- Companies have an obligation to induct new workers. Do companies induct new drivers on their vehicles or is a valid driver’s licence deemed sufficient?

- Is a driving licence a certificate of competence?

- Is a worker’s driving record considered when employing them? Would one employ a driver whose record shows a propensity for speeding?

- Are driving applicants asked whether there is a history of road rage?

- How many demerit points are left on their licence when employed?

- For car driving the same licence is used for personal vehicle use and driving work vehicles. What would happen if the worker has their driver’s licence suspended thereby ending their capacity to drive for work?

- It would be necessary to clarify in what circumstance transport accident insurance applies and when injuries relate to workers’ compensation?

- Who should investigate a traffic incident involving work vehicles – the OHS regulator, police or some other authority?

- Are traffic incident statistics collected for work-related vehicles?

Perhaps ANCAP could begin looking not only at the design of vehicles and additional safety features but also how these matters affect a driver’s perception of their own safety. Does the elevation of the driver compared to other vehicles change the way the driver drives? Could the safety features encourage the driver to drive recklessly? Is technology deadening the driver’s instincts?

Similar questions have been posed in the occupational field for decades in relation to the operation of plant, the safe design of workplaces and the types and locations of safety signage. Now these concepts must be considered for the mobile workplace. Many will find this process challenging with some thinking that it is just another grab by the OHS “fascists”.

The issues do need considerable discussion in workplaces. The recent WorkSafe Victoria “Guide to safe work related driving” is a good starting point but for the development of appropriate policies and, more importantly, to affect cultural change on the matter, companies require an elaboration by traffic authorities and from groups like ANCAP.

No US State has banned the practice because social use of mobile phones has become so widespread that any ban is impossible to enforce effectively.

No US State has banned the practice because social use of mobile phones has become so widespread that any ban is impossible to enforce effectively. The industrialised world, in particular, has been wrestling with the hazard of phones and driving for well over a decade. One

The industrialised world, in particular, has been wrestling with the hazard of phones and driving for well over a decade. One  According to a 2004 report by the US National Highway Traffic Safety Administration reported by UPI (unable to find a link)

According to a 2004 report by the US National Highway Traffic Safety Administration reported by UPI (unable to find a link)

![sa0200906[1]_Page_1 sa0200906[1]_Page_1](http://safetyatworkblog.files.wordpress.com/2009/05/sa02009061_page_1.jpg?w=212) The Northern Territory OHS authority issued a guidance this week about

The Northern Territory OHS authority issued a guidance this week about