Since the 2006 rockfall at Beaconsfield Mine in Tasmania, the public has received limited information. There have been books about the rescue of two workers and the Coroner’s inquest into the death of Larry Knight. Greg Mellick undertook an investigation into the rockfall and found that noone was to blame for the rockfall.

Many workplace disasters have generated royal commissions in Australia. The rockfall did not. However, industry specialists, OHS professionals and others have established an expectation that investigations and reports into industrial disasters are publicly accessible.

The expectation is not unreasonable given that the OHS profession, legal profession, engineers and others operate within a belief that the analysis of disasters can provide ways of avoiding a recurrence. Apparently the Tasmanian Government does not understand the significance of information in improving the safety of workers and the public in its State, even though its OHS and mine safety legislation is structured around prevention.

The Tasmanian Coroner released his findings into the death of Larry Knight. The findings quoted extensively from the 400+ page OHS report from Professor Michael Quinlan that was part of Greg Mellick’s investigation process. But the report itself is yet to be released. Nor has the larger report undertaken by Greg Mellick.

The Director of Public Prosecutions has chosen not to lay charges over the rockfall.

The mine is back at full operation.

The survivors of the rockfall are rebuilding their lives.

Only a couple of weeks ago, the Legislative Council Select Committee on Mining Industry Regulation released its report into the State’s mining legislation. The terms of reference have evolved from the findings of various investigations including Quinlan’s. The committee was required to investigate

- Regulation and workplace standards within the mining and related industries in Tasmania.

- Safety performance of the Tasmanian mining industry compared to other primary industries in the State and the mining industry nationally.

- The role of Workplace Standards Tasmania in the regulation of the mining and associated industries.

- The efficacy and limitations of the co-regulatory model within the mining industry in Tasmania; and

- Any other matters incidental thereto.

On 2 April 2009 at the Safety In Action Conference in Melbourne, Professor Michael Quinlan expressed bewilderment at the decision to not release his investigation report.

SafetyAtWorkBlog contacted the OHS regulator in Tasmania asking for the Quinlan report. We were advised that it was likely that the only way to obtain a copy was through Freedom of Information with the Department of Premier & Cabinet. (DPAC) A representative of DPAC will contact us about the report’s status.

DPAC has a copy of the Mellick report. The Australian Workers Union has a copy of the Mellick report. SafetyAtWorkBlog believes there are leaked copies of the report in existence but for some reason, unknown at this time, the public is not permitted to see the report.

The Queensland government has available four reports into mining disasters in the Moura area with one report going back to 1972!!

In the years after the ESSO-Longford gas explosion, Professor Andrew Hopkins published “Lessons From Longford“. It was for a long time the publisher’s best-selling book. It is quoted extensively in the OHS and management professions. Some of Andrew’s terminologies and concepts of safety culture have become ingrained in the psyche of OHS professionals in Australia.

It is hard to see any reason in April 2009 for the Mellick and Quinlan reports not be be publicly available. Indeed there are many important professional and community reasons for the reports to be seen.

What is the professional legacy of the Tasmanian government’s investigations into the Beaconsfield Mine rockfall in 2004?

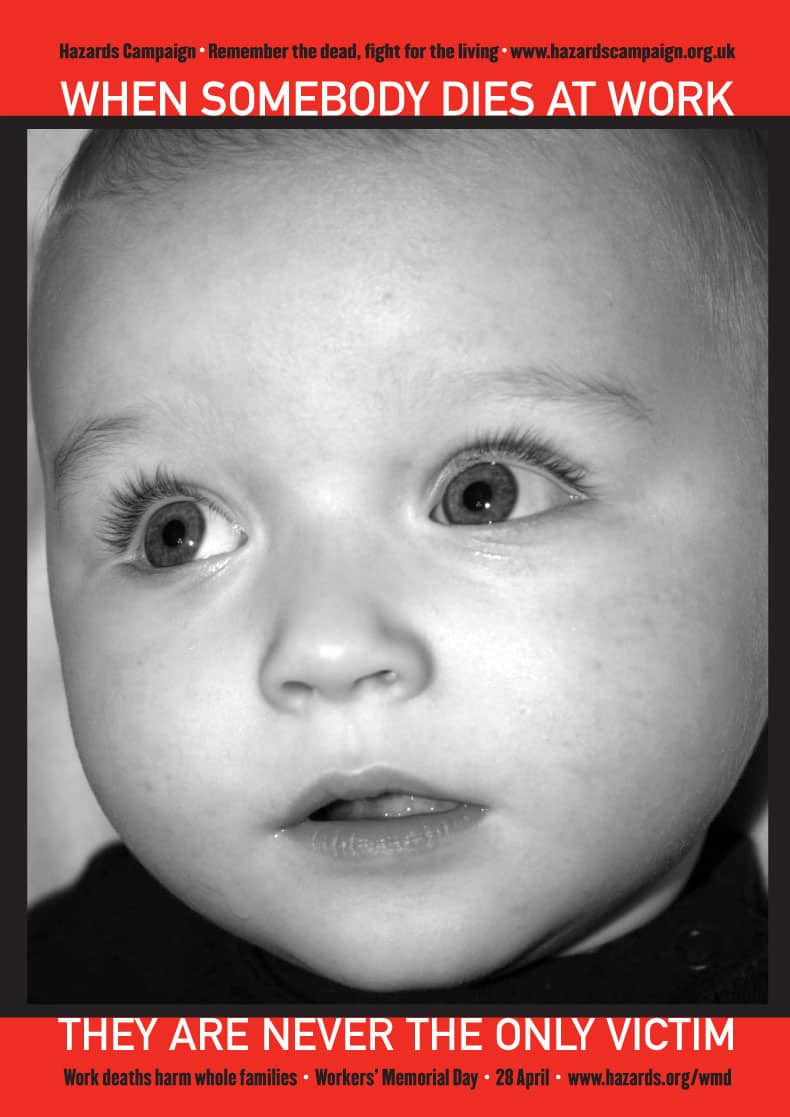

What will the government say when the next rockfall occurs in an underground mine? What will the Premier or the Minister say to the next generation of widows or to the carers of the crippled miners? Certainly David Bartlett or David Llewellyn cannot say that they did all they could to make workplaces safe.