As in most professions during time in occupational health and safety, one meets amazing people. One that SafetyAtWorkBlog cherishes is Melody Kemp.

Melody is an ex-pat Australia who currently resides in Laos. As well as working on OHS matters throughout the Asian region she is also the author of the excellent OHS publication Working for Life: Sourcebook on Occupational Health for Women, a free download.

In 19 December 2008 Melody had an article printed in Asia Times Online concerning the social impacts of a proposed mine on the small Indonesian island of Lembata. In this era of corporate social responsibility, safety professionals have a broad brief which covers many industrial, corporate and environmental responsibilities and it is often company behaviour in far-flung outposts of the corporate structure or the world that indicates a clearer picture of corporate and safety culture.

Melody’s article is highly recommended for those with a social conscience, for those in the mining sectors and for those whose companies have Asian operations.

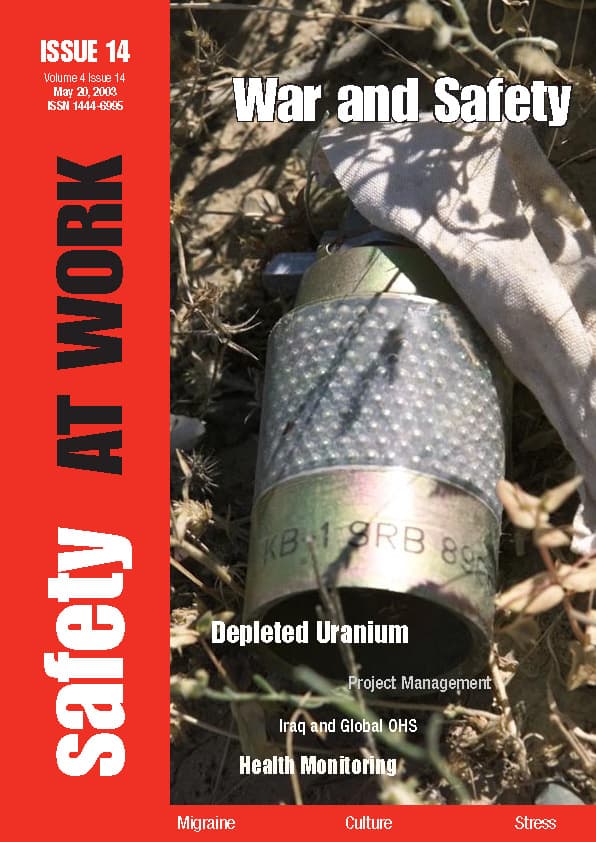

In 2003, Melody wrote an article on the health risks of the use of depleted uranium for Safety At Work magazine (pictured below). That article can be accessed HERE.