In November 2012, the Australian Capital Territory (ACT) government released “Getting Home Safely“, a damning report written by Lynette Briggs and Mark McCabe, into the safety culture and performance of that territory’s building and construction industry. But the Master Builders Association of the ACT has rejected several recommendations and questioned many others, yet refuses to release the evidence that it is assumed would support their position.

In February 2013, ACT’s Minister for Workplace Safety and Industrial Relations, Simon Corbell, accepted all 27 recommendations of the report, much to the surprise of some of us. Corbell said in his media release that

In February 2013, ACT’s Minister for Workplace Safety and Industrial Relations, Simon Corbell, accepted all 27 recommendations of the report, much to the surprise of some of us. Corbell said in his media release that

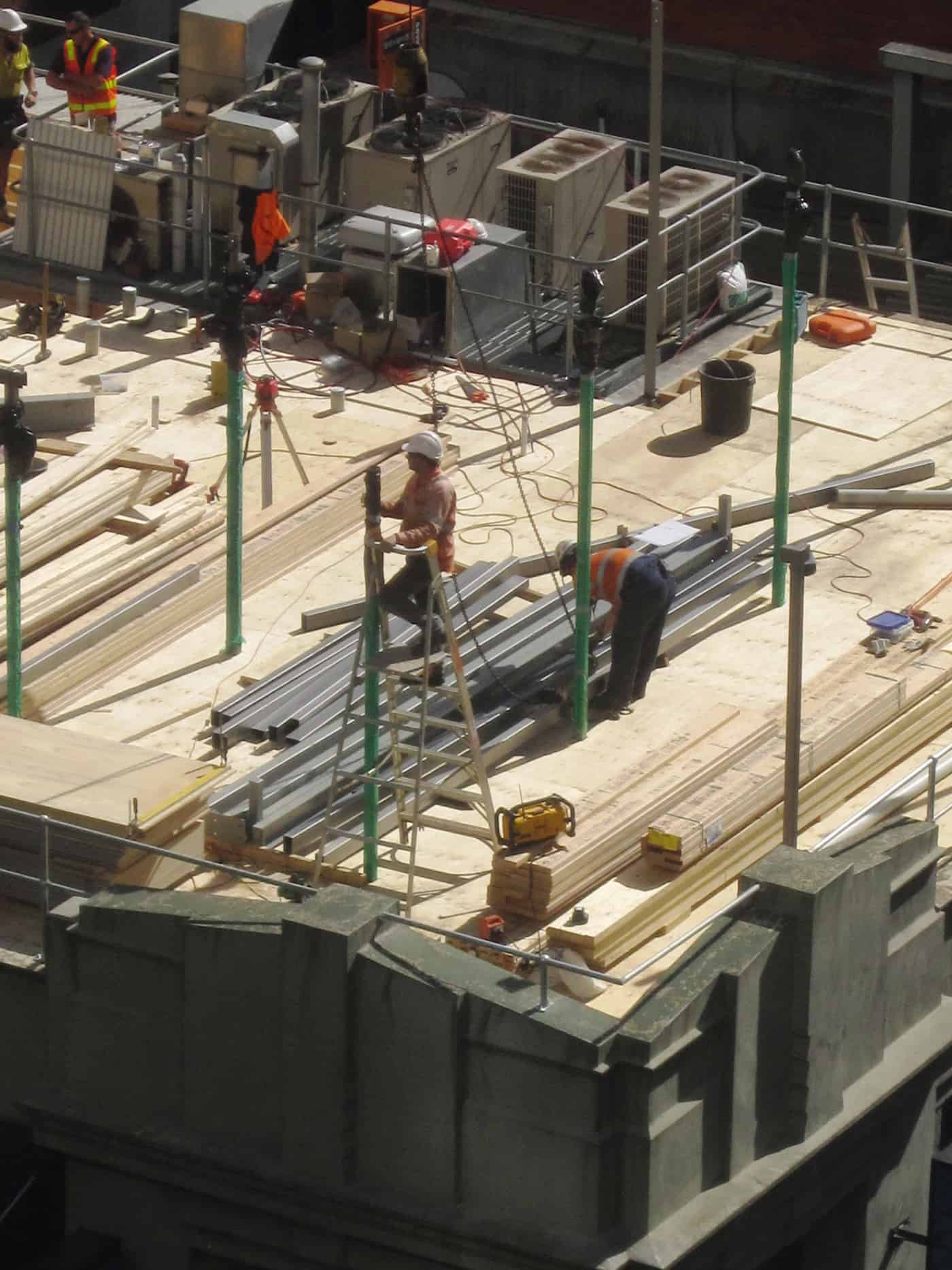

“It is no longer acceptable for people in the construction industry to say there are safety issues in construction sites and then do nothing about them. This report compels unions, employers and government to stand up and actively promote a culture where everyone looks out for their mates, and everyone can go home safely every day…”

“As the report highlights, this is not simply an issue for Government. Safety is an issue for every person on a construction site with principal contractors, sub-contractors, workers, unions and the Regulator all working together.

“The Government expects employers and unions to demonstrate leadership on this issue.”

Safety Leadership or Conspiracy Theory

Today the Master Builders Association of the ACT released its response to “Getting Home Safely” (the Gower review). That response indicates that not all Minister Corbell’s expectations are going to be met with the MBA. In some ways this confirms many of the concerns in the report. Continue reading “Master Builders’ curious response on construction safety”

In 2012, the Victorian Government introduced a

In 2012, the Victorian Government introduced a