For those in the Northern Hemisphere at the moment, the risk of heat stress for workers is an extremely low priority but in Australia, even in the cooler parts and suburbia, the Summer temperatures are tipped to reach 38 degrees Celsius (100 degrees Fahrenheit) over the next few weeks. Away from the urban and coastal centres, temperatures of 45 degrees C and higher will be common.

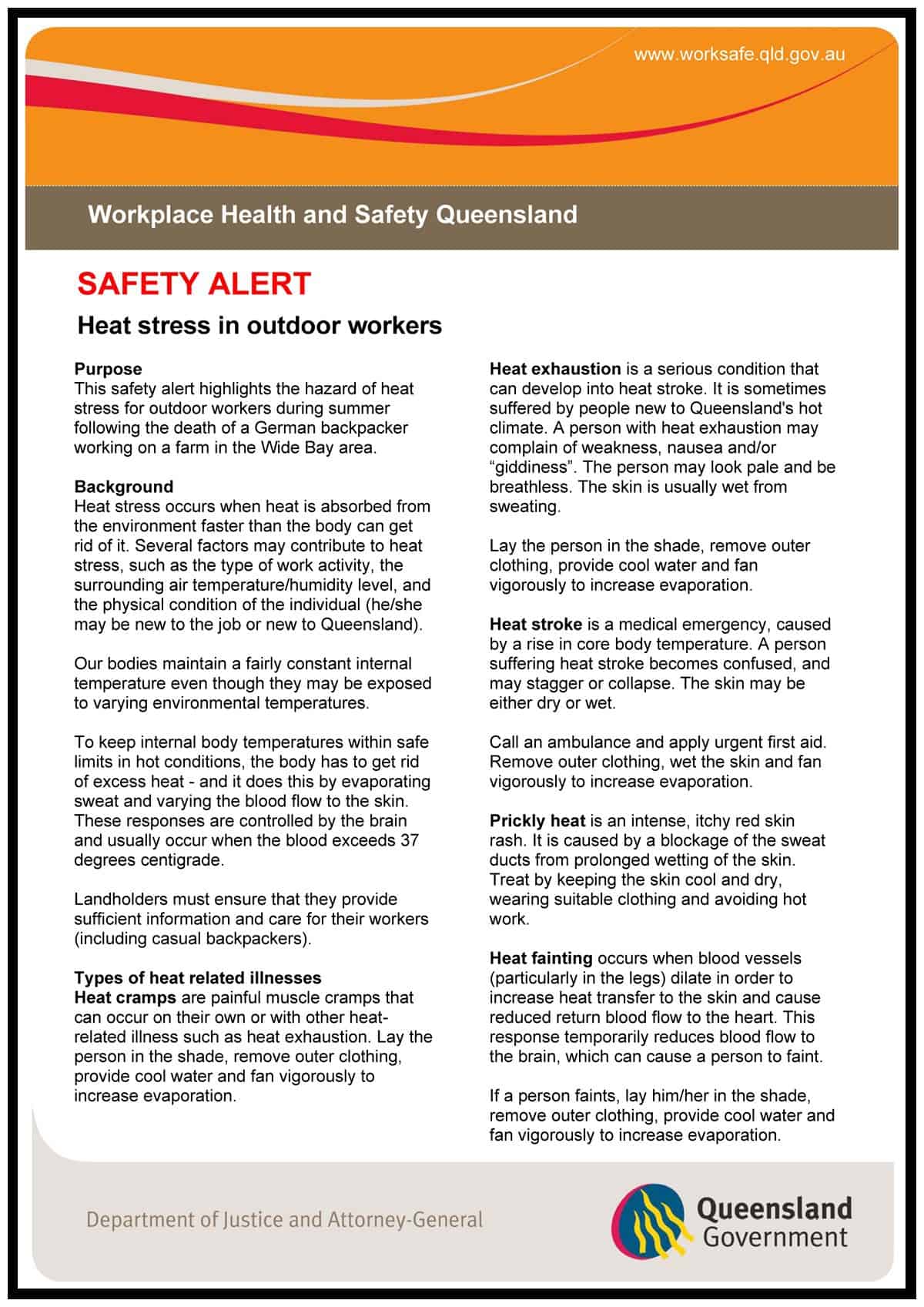

The Queensland Government’s OHS regulator has released new guidance on heat stress. As it was only released on January 5 2010, it is the most current information. The guidance seems aimed at rural workers and particularly those industries which may have a transitory labour force from cooler climates.

The Queensland Government’s OHS regulator has released new guidance on heat stress. As it was only released on January 5 2010, it is the most current information. The guidance seems aimed at rural workers and particularly those industries which may have a transitory labour force from cooler climates.

The guidance is useful in that it recommends some engineering solutions instead of just PPE. For instance,

- “creating some shade structure (tarp, umbrella) or at least find a tree for outdoor workers’ rest breaks

- automating or mechanising tasks that require heavy or physical activity

- reducing radiant heat emissions from hot surfaces and plant e.g. by insulation and shielding.”

Although it would have been good to see some mention of reassessing the need to work in heat at all as discussed elsewhere in SafetyAtWorkBlog.

The Queensland guidance recommends the following heat stress control measures:

- “use sun protection – hat, sunscreen and light sun-protective clothing

- drink at least one litre of cool water an hour when working in the sun

- take breaks during the day in cool shaded areas to enable a rapid return of core temperature to normal

- acclimatise to outdoor work gradually

- have eaten during the day to ensure their energy and salt levels are maintained.

- avoid alcohol, caffeine and drugs which can increase urine output and therefore fluid loss.”