Below is a video of a worker setting up their work area and dusting a retail sign. When one sees such videos or images, we naturally think, “What is he doing?” and “What was he thinking?” This article speculates on those questions and what could have been done.

Category: height

Creating a scaffolding standard that already exists?!

The judgement against GN Residential Construction P/L, part of the Ganellen group, is now publicly available. GN/Ganellen pleaded guilty to work health and safety breaches that lead to the death of a young worker (Christopher Cassaniti) and serious injuries to another worker (Kahled Wehbe), and was fined $900k. The judgement provides much more detail than the media reports at the end of last year, with important information about scaffolding and also a requirement to establish a “Scaffolding Industry Safety Standard Working Group”. The curious part of this latter requirement is that New South Wales has had an industry standard for scaffolding since 2008.

Many safety lessons from one workplace death

The Coronial Finding in to the death of Jorge Castillo-Riffo is an important occupational health and safety (OHS) document. It discusses, amongst other matters,

The Coronial Finding in to the death of Jorge Castillo-Riffo is an important occupational health and safety (OHS) document. It discusses, amongst other matters,

- A curious attitude from SafeWorkSA

- The role of Safe Work Method Statements and risk assessments

- Using the right plant for the right task

- Contractual relationships

- Construction methodology.

More issues than these are raised in the Finding and I urge all OHS people to read the document and reflect on the OHS management in their workplaces.

Scissor Lift death findings clarify the context of OHS

If all you knew about occupational health and safety (OHS) was what you read in the physical or online newspapers , you would not know anything about safety management – or maybe anything positive. It takes being involved with managing safety in the real world to understand how OHS operates in the real world. But even then we only learn from our own experiences.

If all you knew about occupational health and safety (OHS) was what you read in the physical or online newspapers , you would not know anything about safety management – or maybe anything positive. It takes being involved with managing safety in the real world to understand how OHS operates in the real world. But even then we only learn from our own experiences.

The 92-page coronial finding into the death of Jorge Castello-Riffo, released last week, is a tragic and detailed case study of OHS in the real world and should be obligatory reading for OHS professionals and those trying to understand the push for increased OHS, penalties and corporate accountability. Below I look at just one section of the Coronial Findings in this article – the Coroner’s responses to a set of proposed recommendations.

Is this scaffolder safe?

A SafetyAtWorkBlog reader sent through the video below. On the far right of the dashcam footage a scaffolder appears to be erecting scaffold while several floors up, holding onto one of the existing poles and without any fall protection. Continue reading “Is this scaffolder safe?”

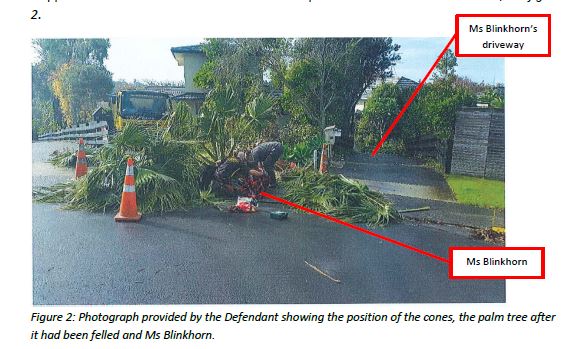

Prosecution over fallen tree threatens small business viability

A recent occupational health and safety (OHS) prosecution in New Zealand illustrates many issues and attitudes to safety held by small business operators around the world.

Heights, Standards and Safety

Engineering and design Standards have existed globally for a long time. They have considerable authority, often provided through legislation, and underpin many of the safety devices and equipment used in workplaces. But does compliance with Standards mean that something is safe?

Engineering and design Standards have existed globally for a long time. They have considerable authority, often provided through legislation, and underpin many of the safety devices and equipment used in workplaces. But does compliance with Standards mean that something is safe?

The easy answer is no. A recent presentation to the Central Safety Group (CSG) by David Davis of the Working at Heights Association illustrated this gap between workplace safety compliance and compliance with Standards.