In 2010 Queensland’s former Attorney-General Cameron Dick said of enforceable undertakings that:

“Enforceable undertakings promote the introduction of long-lasting and more wide-ranging safety changes that would not have occurred under the prosecutorial system that imposes fines after the event.”

Enforceable Undertakings can be a powerful force for improving occupational health and safety (OHS) but they could also be used by employers to forestall investment in OHS and minimise the financial penalties should an incident occur.

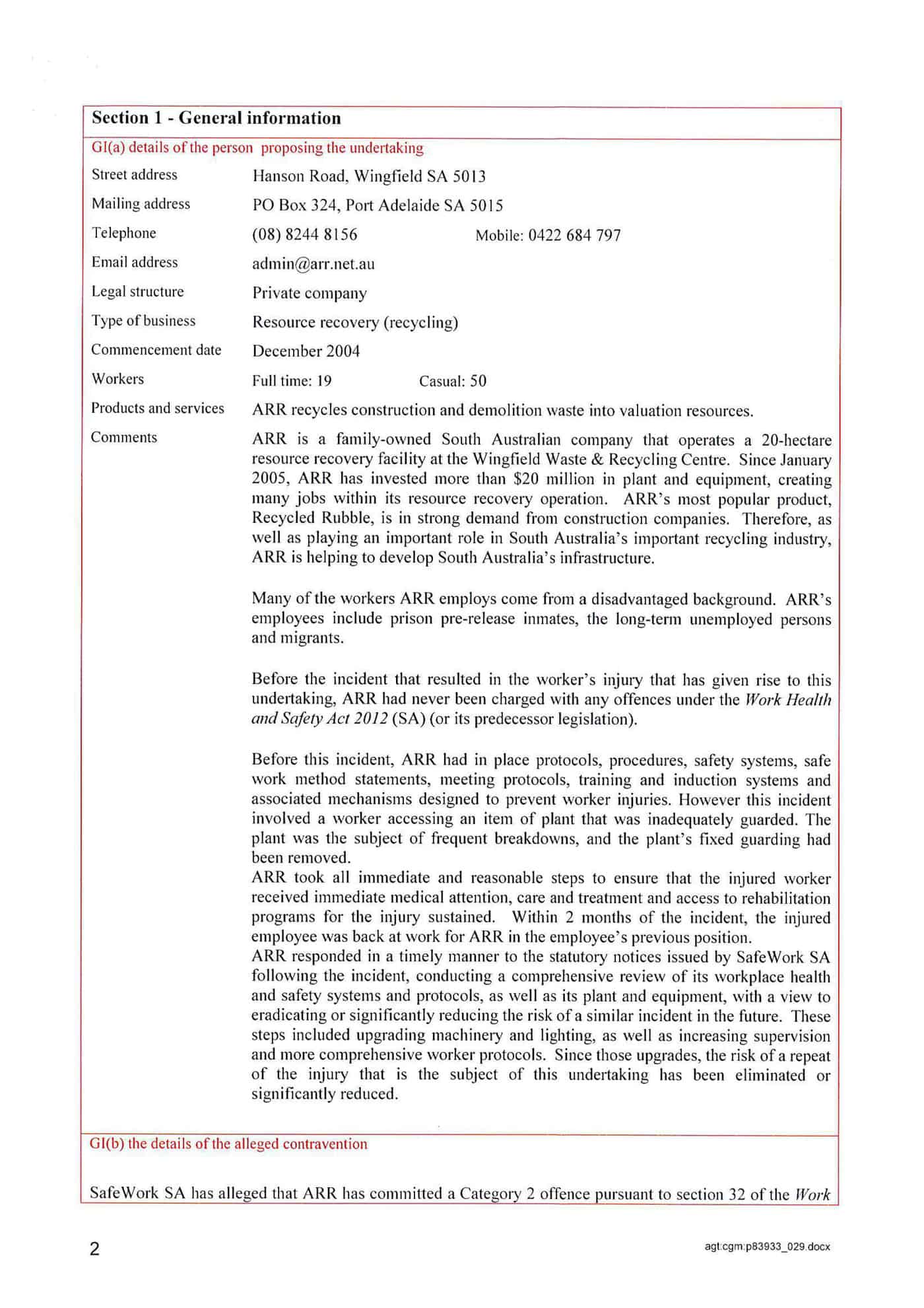

Australian law firm Sparke Helmore has released a prosecution summary of legal proceedings by SafeWorkSA about the application of an Enforceable Undertaking to Adelaide Resource Recovery Pty Ltd (ARR) over the severing of a thumb tip in May 2015. The company had no previous record on occupational health and safety (OHS) breaches and, although the company had plenty of the standard OHS policies and procedures, the conveyor machine mechanism was inadequately guarded – (OHS-101). ARR has spent over $A215,000 on rectifying the workplace in return for the dismissal of legal proceedings.

Australian law firm Sparke Helmore has released a prosecution summary of legal proceedings by SafeWorkSA about the application of an Enforceable Undertaking to Adelaide Resource Recovery Pty Ltd (ARR) over the severing of a thumb tip in May 2015. The company had no previous record on occupational health and safety (OHS) breaches and, although the company had plenty of the standard OHS policies and procedures, the conveyor machine mechanism was inadequately guarded – (OHS-101). ARR has spent over $A215,000 on rectifying the workplace in return for the dismissal of legal proceedings.

Taking this case as a discussion point, a company could avoid a prosecution and potential fine for an OHS breach by suggesting it fix the causes of the breach/incident through an Enforceable Undertaking. It may be argued that by suggesting an enforceable undertaking a company can turn a potential (large) fine into the (lower) cost of improving OHS at their workplace that, if it had spent that amount already, could have prevented the incident. A company could risk safety incidents by under-resourcing on OHS and wait for an incident (hopefully not life-threatening) at which point it can spend the money on the safety resources that it should already have had in place.

It is worth looking at the commitments that ARR has made in its enforceable undertaking. Almost all of them are the actions and resources that an OHS regulator would expect companies to have already, in order to comply with OHS laws:

- “installing appropriate guarding to the machine,

- upgrading lighting in the area,

- hiring an additional construction and demolition shed supervisor,

- employing a site safety supervisor.

- committing that the behaviour leading to the alleged contravention had ceased and would not reoccur

- committing to ongoing effective management of WHS risks

- committing to disseminate information about the undertaking to relevant parties

- committing to participating constructively in all compliance monitoring activities of the undertaking

- retaining the additional construction and demolition shed supervisor, and ensuring they conduct spot audits, site safety walks and revising the Safe Work Method Statements in consultation with workers

- retaining the site safety supervisor

- publishing a safety hazard alert for its industry on the importance of adequate guarding

- having a representative speak at a forum conducted by SafeWork SA

- assisting in running a training program conducted by Mission Australia, and

- paying SafeWork SA’s costs associated with the undertaking.”

(More details, and costs, of actions undertaken are available in ARR’s Enforceable Undertaking)

The use of Enforceable Undertakings is a positive move in OHS penalty options in Australia but it may also provide opportunities for exploitation for which OHS regulators need to watch.

ARR’s use of the undertaking makes economic sense. As Sparke Helmore point out, the company could have faced a maximum penalty of $A1.5 million for the incident but instead has reinvested over $A200K into its own operating and OHS systems. The Enforceable Undertaking has saved ARR a lot of money and avoided a prosecution.

The update of the OHS resources by ARR is to be applauded, but it should not be forgotten that all of this activity seems to be bringing the company to the level of OHS compliance that all employers are expected to already have.

More information on Enforceable Undertakings in South Australia is available HERE

Brad, most companies (if not liquidated) would invest in improving OHS following action, or prosecution, by the OHS regulators but the public wouldn’t hear about. We would only (usually) hear of the prosecution and penalty.

The Enforceable Undertaking details what the employer/PCBU will do and so we have a better idea of not only the non-compliance but what might have led to that non-compliance or incident, and, in ARR’s case, the costs associated with the remediations. So ARR’s EU deserves a close reading (it is good see so many readers clicking through to the source material).

The introduction of the Work Health and Safety laws relied (wrongly in my opinion) on court cases to clarify responsibilities, refine “as far as is reasonably practicable” and to iron out inconsistencies. The EU can be seen as part of that process.

I’m all for proactive development, but isn’t this Reactivity at its best? Why should an employer only start being proactive after the fact, and then be forced to maintain that pro-activity??? Aren’t the orders within an enforceable undertaking supposed to be what the employer should have done to assure safety in the first place??? EU’s seem to be a benefit after the fact that someone has been disabled or deceased at work. Why aren’t enforceable undertakings automatically attached to prosecutions and removed as an option for preventative prosecution. If the enforceable undertaking is a good incentive for improvement after the fact, surely it would be more effective if attached to a prosecution with the incentive re prosecution becoming considerably more severe upon non conformance or repeat occurrences.

Do the poorer performing employers out there simply rely upon an EU as a ‘get out of jail for free’ deal???

Enforceable undertakings can also be viewed as community service correction order.

How many people convicted of crimes are currently undertaking community service correction orders around Australia? The impact is minimal and most persons will continue to commit other offences due to the leniency of the courts.

An enforceable undertaking can be a real driver for implementing best practice initiatives while it has momentum and the regulator is overseeing the undertaking, but after that what happens??

Buddy, I think the amount of oversight by OHS regulators during the Enforceable Undertaking is good and would not expect the regulator to continue after the period ends as OHS remains the employers’s/PCBU’s responsibility. it could be argued that the company’s reputation is at higher risk because it has already been found wanting but I am very suspicious of reputational risk as an OHS motivator.

I also wonder if an Enforceable Undertaking encourages OHS “best practice” (whatever that is). The ARR situation seems to me to be bringing the company to compliance only. If the company builds on the changes to beyond compliance, that is good but we’ll have to wait and see.

Although I don’t disagree that the company should be doing those things anyway … fines in SA don’t tend towards the the higher end (particularly for first offences) and many companies fight and successfully dodge fines anyway. I see this option (for SafeWork SA) as a useful tool to be able to drive long term change. Even if fined a company may not make the changes they should, but with an undertaking they are legally obliged to do this in order to avoid prosecution. The Workers are better off under this option.

SafeWork SA made a legal technical error recently and had to change the laws to enable them to prosecute several employers and even now if the companies Lawyer up they might still get away with it.

I would encourage Employers to go down the Undertaking path if it is an option. I see it as a Win Win.

Tim, I read about SafeWorkSA’s extension of its deadline for prosecutions. It did seem it was a change after a cock-up rather than a change of its system. – http://www.sparke.com.au/insights/retrospective-safety-legislation-passed-in-sa/

I agree that the workers will benefit from Enforceable Undertakings as safety management and resources improve but the non-compliance that led to an incident should not be forgotten.

In an ideal world I would agree with you, however on balance I think the best outcome for workers is the one that results in a safer workplace for them. The undertaking guarantees change for the better, prosecution is simply punishment for the company and makes no guarantee of better future safety performance.

On the SafeWork SA blunder, it was definitely a mistake, however it appears to be a technical one, with the new person in charge of SafeWork SA not being technically able to make a prosecution against the old laws. They changed for the new laws and then forgot to ensure they were still legally able to prosecute under the old ones. I do agree they should have allowed time for any errors to be fixed, but the practice of putting off prosecutions to the last hour has also probably resulted in some cases being won because they took the time to do their homework properly also.

Under resourcing is the real issue, and in the current economic climate I don’t see that improving anytime soon.

Enforceable undertakings can be a real driver for implementing best practice initiatives that could not only benefit the PCBU but to an industry group thereby raising the bar, not merely being compliant. But as this case highlights all too often regulators allow companies to avoid penalties associated with safety breaches, when there is clear evidence that the company had allowed unsafe work environments that did not comply with the law, and should have been remedied by the issue of improvement notices or if necessary prohibition notices.

It is up to the regulator to accept an enforceable undertaking. They should not allow a person or business to avoid prosecution and then accept measures as part of the undertaking that amount to mere compliance of a PCBU’ s existing obligations to provide a workplace that is Safe and without risk to health.

And this meets the standards set out in WHS legislation that was championed by so many state governments ?