Guest contributor David Robertson discusses the differences between risk simulations and real risk data in relation to quad bike safety:

“The motion picture blockbuster “Avatar”, for the time we are in the cinema, would have us believe that Sam Worthington can turn into a giant blue man on a faraway planet. James Cameron used computers to deliver us this illusion. In science (and particularly with safety) we must be able to distinguish between computers that are valuable tools and computers that don’t represent reality. Dynamic Research, Inc.(DRI) chose 113 actual quad bike (ATV) accidents to simulate in a computer model.

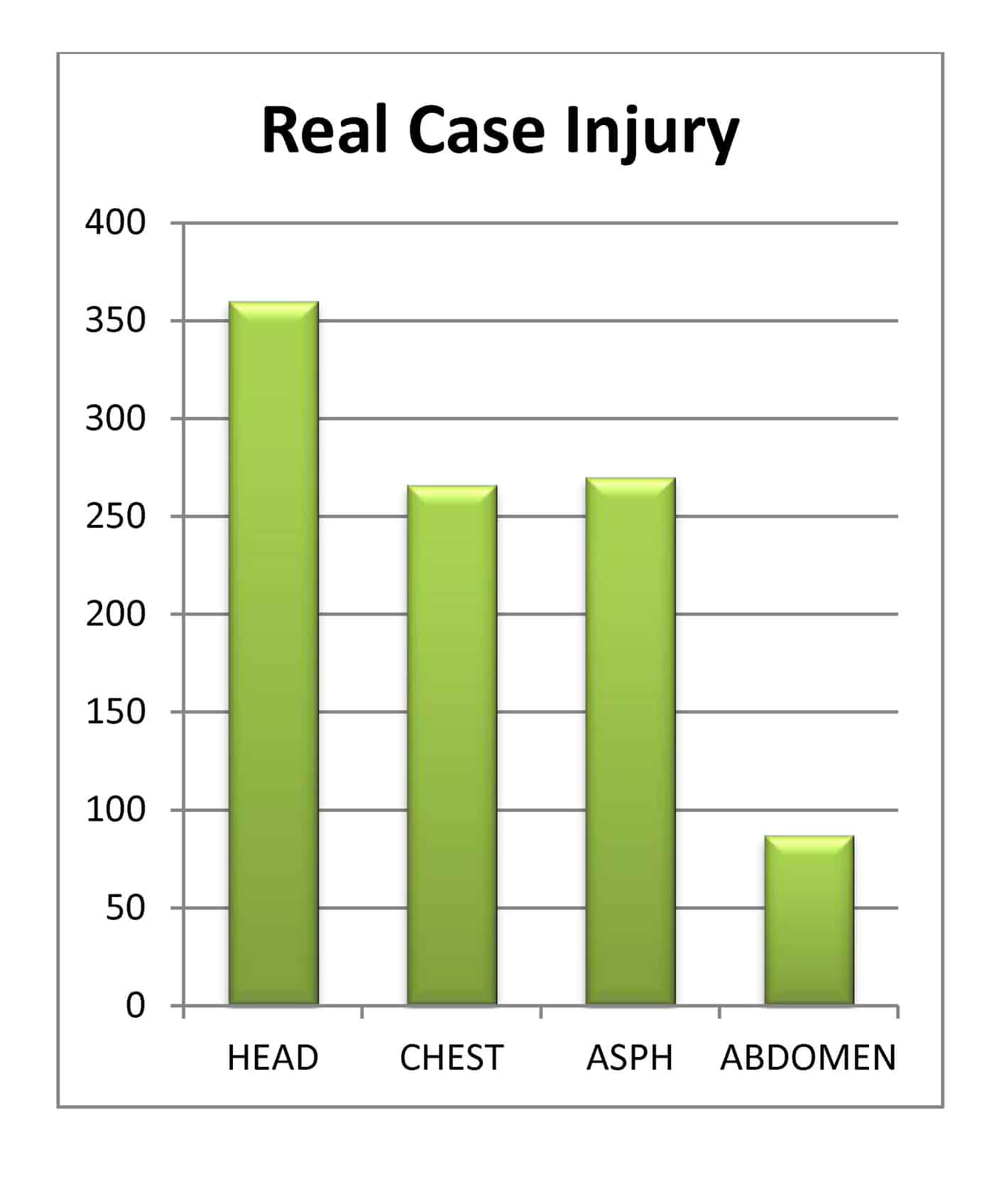

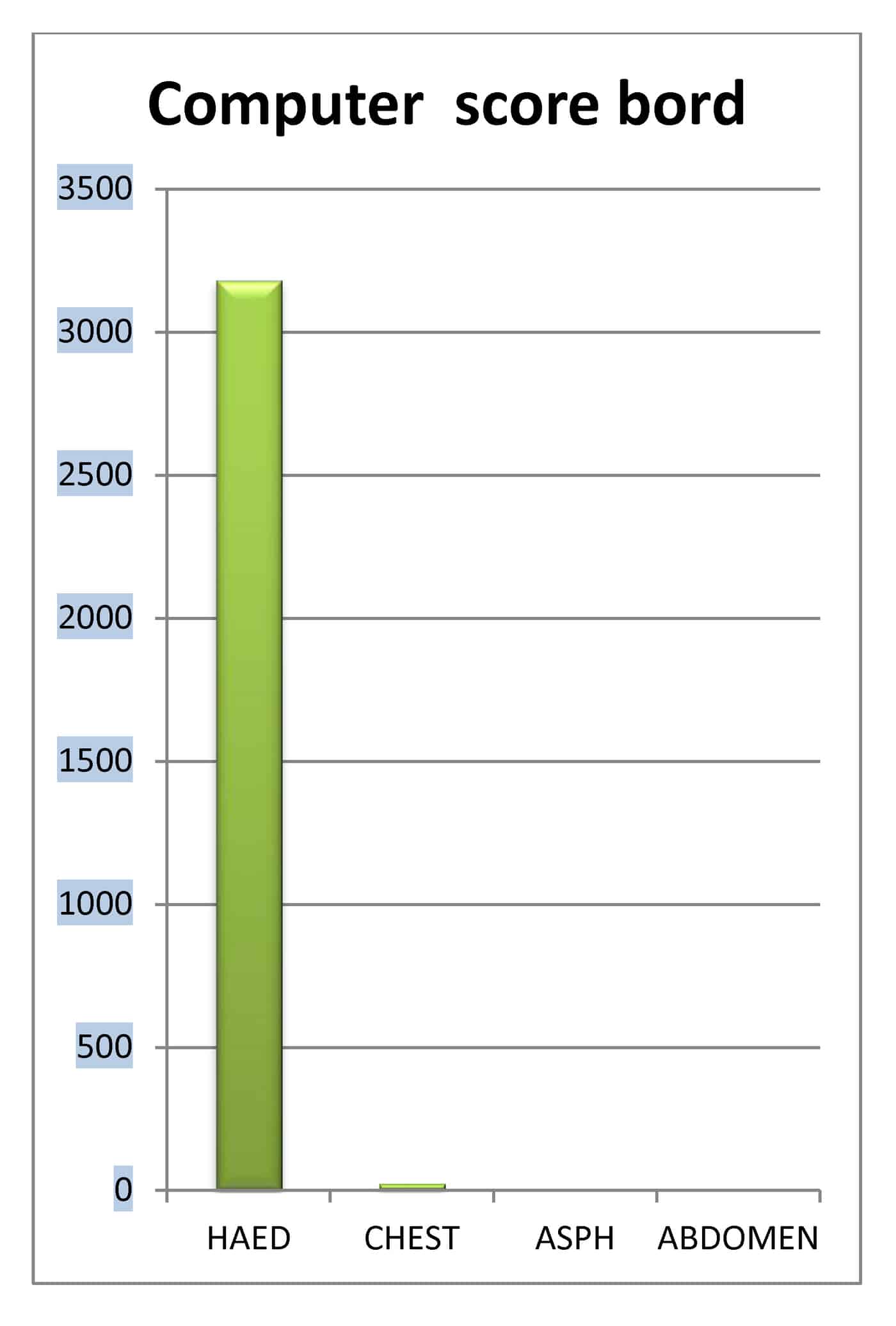

The first table below shows the injuries DRI record as what really happened from all the 113 cases, but represented as approximate normalized injury cost (ANIC)*. When DRI’s computer runs the same cases, one would expect a similar result. The results are shown in the second table (ANIC), note the scale on the left has had to be changed (table 2 should be about 10 times taller if the same scale in table 1 was used) because head injuries rose from 360 points to well over 3000. Equally astonishingly is that abdomen injuries have vanished altogether and chest injuries dropped from 266 to a next to nothing (23). Asphyxiation was not even included in the computer model.

Remembering that computer modelling is only a tool. It is a fundamental part of science to establish your tools are accurate and representative, if they are not they must be tuned until they are or disposed. The two tables are light-years apart in their results depicting the real life cases and DRI’s computer simulation and therefore DRI’s computer simulation can’t be relied on.

The question for some that are unfamiliar with computer simulations is why? The short answer is, were DRI to plug a solution into their computer, say a “helmet”, the computer is very “happy” because you have dealt with the over-exaggerated problem of head injury. But if DRI’s computer is asked to deal with a rollover protection device it gets very “angry” and says don’t be silly, there is no problem with chest, abdomen or asphyxiation. I it doesn’t know any better.

The fact is that it is more than probable that any safety system that is not very, very effective in dealing with head injuries is doomed to failure if assessed by DRI”s computer.”

*For clarity only body regions and causes where fatalities were recorded are displayed (leg, face and neck injuries are excluded).

Jai

Your comments appear perfectly rational to you, but fail to understand what is available, and safe systems of work.

The best commercially available rollover resisting devise is no higher than the riders head.

Further to ride a quad bike under an overhung branch lower than your head is inherently dangerous as obviously your line of sight is limited. In addition a moments distraction could result in serious head/ neck injury. A safe system of work would be that no one rode under such a low branch.

And the best commercially available rollover resisting devise is so light it has virtually no impact on stabilility – the rollover moment generated by the devise is 3% of the rollover moment of the quad bike plus rider. In contrast a full spray tank will have a rollover moment equal to % of the rollover moment of the quad bike plus rider.

as a owner of a quad bike myself which also gets used in the workplace on cattle properties the use of rops is a good idea in theory. i also do alot of work in the mines where safety is no. 1 priority. countless times have i seen where over engineering of a product that is already safe enough for the job at hand makes it harder for the job to be done, which in turn can make the attitude of the worker to take risks to do the job which would not normally need to be taken if it wasn\’t for the modification of the original design. same goes for the rops on quad bikes, the use of bikes on the farm varies from fencing to mustering and bull catching, the addition of rops to the bike in these jobs especially mustering where the rider has to chase cattle through bush at speed brings additional risks that get introduced with rops for example getting hung up on trees, the bikes handling being changed with the extra weight and the weight being over center. There is a point where over engineering of an already safe product can be more dangerous. What really needs to be looked at is the attitude of the workers and the risks they take and the training they get before being allowed to use quad bikes in the work place. the reason why quad bikes are popular on farms is because there design is practical in there current design.

Please refer to NZ Health & Safety In Employment Act 1992 where at Section 18A of the act ; Duties of persons selling or supplying plant for use in place of work

(2) A person who sells or supplies (other than in a situation covered by subsection (1)) to another person plant that can be used in a place of work must take all practicable steps to ensure that the plant is designed and made, and has been maintained, so that it is safe for any known intended use or any use of that plant that the person could reasonably expect.

Given the above legal requirement, how can Quad bike manufacturers and dealers sell their product to farmers in current design given the clear evidence of roll-over hazard? I have asked the Minister of Labour and her department to explain this.

This makes it even more important that, when you buy a quad bike for commercial use, that it is fit for purpose. Too many people are unaware of the correct safety gear to wear when riding quad bikes, and in the UK we often see children riding around on the roads with no crash helmets and no road training whatsoever.

Dave: You are in the same boat as the inventor of the chain saw bar guard that would have effectively mitigated all kick-back injury. I had the experience of seeing first hand how the standard committee involved essentially followed a large manufacturer\’s wishes, and denied the bar guard an existence. That was many years ago in Tasmania. I note that there are a number of variants to the original idea now in existence, but the regulators and manufacturers have not adopted this engineering control; rather they continue to rely on administrative controls.

I think Yossi\’s idea is a good one, but maybe as a workshop of interested stakeholders as the target to provide a public platform to debate that the manufacturers would then have to address?

In relation to your last response

Dave,

about my suggestion of a public conference. It\’s worth airing this discussion on this blog: You optimistically suggest that a group of engineers could settle this once and for all. Trawl through the history of OHS around the world and see if you can find any one occasion where an engineering solution – simply as an engineering solution – ever fixed any OHS hazards.

Maybe someone can point to some such occasion where a group of engineers without any social (or socio-occupational) legal) or political pressure fixed an OHS problem simply by reason and logic.

As an example, when the radar was invented to help with very serious safety problems for shipping why did the number of safety incidents go up?!

I wish you luck with your \’group of engineers\’ but I can\’t remeber any group of professionals speaking with one voice on issues of OHS or even being certain enough to create a single position; I wish it was as simple as that.

The asbestos conference I mentioned in my earlier note created a furore because of weight of evidence and union pressure. And, of course, Selikoff personally.

Marian, “admission of guilt” but who is guilty? A question I have always asked myself since becoming involved in this issue. My blog is about DRI’s computer simulations, but many comments have been about the manufacturers. I have wondered if DRI have been “acting like a lawyer in a criminal trial”, trying to defend the position of a client, or have the quad bike manufacturers based their position on DRI’s computer simulations? Either way, it’s all wobbly ground.

Some readers may find some of the conference papers and presnetations at the Farmsafe WA conference of use on the quad bike issue – http://www.farmsafewa.org/page/National-Conference.aspx

Dave, I didn\’t want to give the impression that this fact gets them off the hook. Of course the designers have a responsibility to make them safe for workplaces. I suspect there\’s a fear by the bike makers that adding rollover protection would be some sort of admission of guilt.

Marion – you raise a relevant point, however, in Australia and New Zealand quadbikes are, for the large part, specifically marketed, or at least \”known\” to be used in workplaces and therefore must be fit for use.

From what I understand, it\’s not so much that the bikes are not suited to Australian conditions per se but they are designed for the massive international recreation market rather than for farm use.

Yossi, I think your conference idea would be a great vehicle for airing significant issues about quadbike safety, however, I have now learnt from 6 years of doing this, the little guy never wins over the polished performances of larger companies at any type of public forum. If the current stance of the quadbke manufacturers is taken to such a conference, they are likely to commandeer the ear of the media and nullify the effect of the conference. I suggest, we first ask the following questions:

Do the quadbike manufacturers rely solely on DRI\’s work to determine their current position on the issue? (As I understand, this is the case)

Is DRI\’s work of an acceptable standard to even allow it to be brought to the table? (as per evidence provided in the article above – no it isn\’t)

I believe a group of Engineers could settle this once and for all, so that we can at least start off with a premise that roll over protection has the potential to be an effective engineering solution.

I\’m as a guilty of procrastination as the next bloke, but gotta say OH&S-World is rife with it. For mine, the evidence and testing QuadBar has done and presented on its web site make it bleedingly obvious that a roll-over bar is a smart move on a quad bike. Given the slowness of OH&S regulators to act on the obvious, putting aside NZ, I think all that can be done is for farming clients to be advised in the strongest possible terms that they are quite literally nuts if they don\’t fit a roll-over bar – that\’s what I did with mine.

In 1964 in the US Professor Irving Selikoff presented his latest data on asbestos effects at a famous international conference, \’Biological Effects of Asbestos\’. This was the point where the asbestos industry had to start taking serious note of the tragedies associated with this substance. Nothing changed dramatically, sales still went up (!), but in many ways this was a turning point in the debate.

Whilst I\’m not comparing quad bikes\’ tendency to roll to asbestos, I am pointing out that a continuing struggle (such as Dave\’s) with an industry about matters OHS is seldom resolved by science and reason alone, or even by morality.

A good, in depth, open, international conference – held in Australia – dealing publicly with the obvious and getting a lot of media coverage would be very useful. Clear and accurate topics would be set for speakers to address so it doesn\’t just become a partisan talk fest – including industry speakers.

Aside from that I believe it will be a long long struggle and in the end – I fear – like with the lead industry and the related exposure standards, things will only change after key court cases.

So, in effect, we break our own rules by allowing the importation of these bikes in their current form which are a known death traps.

Am I reading the comment correctly Kevin? in that we are at the mercy of overseas manufacturers policy? I would have thought an improvement notice advising all quad bikes must be fitted with roll over protection in the same manner as tractors, served on the resellers would suffice.

Given that these bikes have been well and truly identified as a safety hazard in the work place one, would have thought that they are subject to the same rules as other machinery.

As for David having a vested interest, I say more power to him. David and his like are to be applauded for there enterprise in supplying practical solutions to identified problems. As is the norm, there seems to be far more effort spent on consultation, discussion, ruminating and mastication of identified safety problems as opposed to good old fashioned application of grey matter to provide a realistic and provable, practical engineered solution to those problems.

The only things manufacturers of these infernal machines are worried about are cost and aesthetics.

David Robertson has been battling the quad bike manufacturers for years to gain the ear of the OHS regulators for his rollover-protection structure (ROPS) to be recognised as a suitable risk control measure.

The manufacturers have been working on a industry-based code of practice for quad bikes for a long time and in October 2010 have participated in yet another consultation process with Dave and others on the safety of quad bikes.

Australia is a small percentage of the world\’s quad bike market, a market dominated by US manufacturers. Dave\’s battle – to gain some recognition for his ROPS – in some ways reflects the perennial problem of local manufacturers needing to \”make imported equipment safe\” for local use.

It is a legislative obligation that imported plant is safe for use in Australia. Plant sometimes needs to be rewired, relabelled, sometimes redesigned. Cars need to be manufactured for right hand drive for local Australian conditions but, for some reason, quad bikes can come into Australia unchanged. Not only that, according to Dave Robertson, the manufacturers refuse to allow the quad bikes to be made safer by the fitting of a quadbar ROPS.

Dave Robertson continues to fight large companies that have large resources, large research budgets and great political influence. It is true that he is a commercial manufacturer of a product, so has a vested interets, but his product has the potential to save lives and to save lives in one of the industry sectors that Australian and New Zealand OHS regulators acknowledge is over-represented in workplace fatality data, farming.

It is perhaps useful to ask what harm could there be in allowing the quadbar safety device to be fitted to quad bikes, if such a device can save a life?