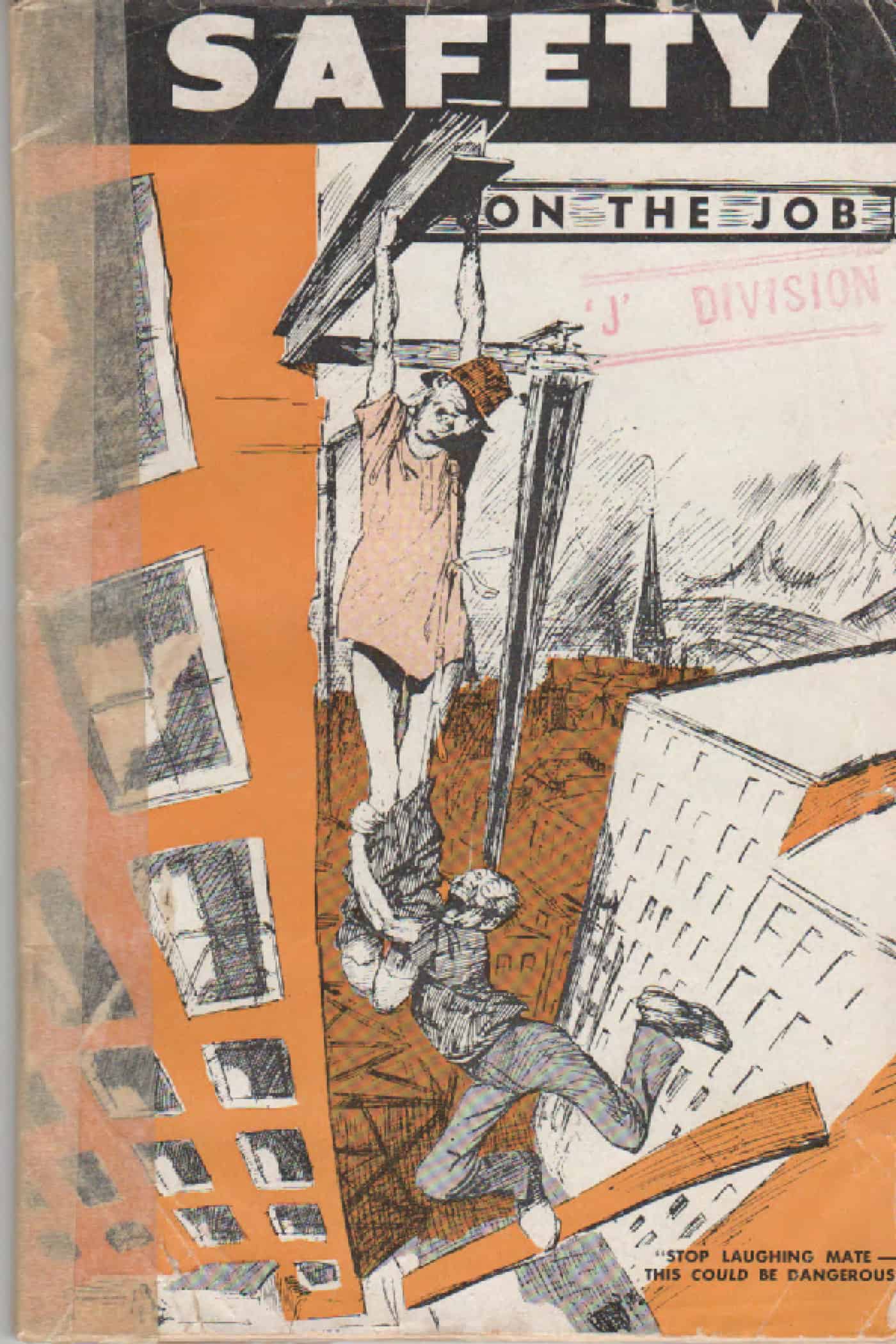

A safety colleague showed me an old book about workplace safety that his father had found in a book sale. It’s called “Safety on the Job” and was produced by the Master Builders Association of Victoria “for free distribution to the Building Trade” around 1959. The cover mirrors the iconic Australian cartoon from 1933 by Stan Cross.

On the cover is a stamp saying “J Division”. J Division was part of Melbourne’s Pentridge Jail, the section for:

On the cover is a stamp saying “J Division”. J Division was part of Melbourne’s Pentridge Jail, the section for:

“Young Offenders Group – Later for long-term with record of good behavior”

The publication is not specifically designed for young workers but there is some excellent information, for the time, included on “standard crane whistles”, explosive power tools regulations and trenching.

Most intriguing is the chapter “Common Sense Suggestions for Managers, Supervisors, Foremen and Safety Officers, etc.” It is surprising how many of the suggestions remain relevant today. Perhaps the booklet was trying to generate common sense rather than reflecting it. Below are the first ten suggestions.

- “When you make your daily rounds it is your job to make them a hazard-hunting inspection as well. You have special opportunities to spot deficiencies and dangers. By neglecting to arrange for necessary guards or fencing you may lay both yourself and the firm open to legal proceedings.

- Warn all workers of dangers in their work and show them the correct way.

- Try, in particular, to see your job from the point of view of new workers. What is familiar to you will be fresh to them, and should be explained.

- See that new workers are put in the charge of an experienced hand. Some people are much better than others at helping the newcomers. Choose the better ones.

- Remember that new workers not only need telling; they need watching as well. They may be clumsy or awkward, or, being new to the job, may not have clearly grasped the meaning of instructions. They can be a danger to others as well as themselves.

- See that all workers comply with accident prevention rules.

- Instructions sometimes are disobeyed because people do not understand the really sound reasons for them. Bear this in mind and be ready and willing to explain your orders as often as necessary.

- If a worker on the job is constantly running into danger, consider whether he could be transferred to work that is less risky.

- The accident record in your project is matter for your concern. Do all you can to keep the figures down. Every foreman should know and report regularly to management upon the accident record of the men under his control. Management should act at once to discover and remove the cause of any “peaks”.

- Remember that clear passageways, tidiness and general good housekeeping is essential for the prevention of accidents.”

In modern parlance this common sense could equate to

- Walk the site, identifying and fixing hazards.

- Talk and teach workers about safety.

- Assess your workplace with fresh eyes.

- Pair new workers with proven mentors.

- Supervisor new workers until they are no longer a hazard to themselves or others.

- Follow the site safety rules.

- Explain the justification for the site safety rules and procedures.

- Match the worker to the job.

- Watch the project safety statistics and act on any negative trends.

- Keep the site tidy and safe.

Perhaps our grandfathers knew what they were on about. But then if these rules still retain relevance fifty years later, does this show that we just don’t learn?

\”Talk and teach workers about safety.\” Even though the concept sounds incredibly simple, it is amazing how many businesses overlook this one suggestion. Workers, especially young workers, may not understand the severity of some situations and what safety procedures need to be taken, or why. Training and communication are the keys to fostering a safe workplace environment.

\”Talk and teach workers about safety.\” Even though the concept sounds incredibly simple, it is amazing how many businesses overlook this one suggestion. Workers, especially young workers, may not understand the severity of some situations and what safety procedures need to be taken, or why. Training and communication are the keys to fostering a safe workplace environment.

\”Talk and teach workers about safety.\” Even though the concept sounds incredibly simple, it is amazing how many businesses overlook this one suggestion. Workers, especially young workers, may not understand the severity of some situations and what safety procedures need to be taken, or why. Training and communication are the keys to fostering a safe workplace environment.

\”Talk and teach workers about safety.\” Even though the concept sounds incredibly simple, it is amazing how many businesses overlook this one suggestion. Workers, especially young workers, may not understand the severity of some situations and what safety procedures need to be taken, or why. Training and communication are the keys to fostering a safe workplace environment.

Not necessarily that we don\’t learn Kevin, but that every new wave of employees need to learn the same lessons.